Close to Home...Post #6 - Anderson Ranch wool

/Last March I watched some of the shearing on a large sheep ranch in southern Solano County and I brought home fleeces. Here is the blog post from that day.  In September I got the yarn back from the mill and used it for pieces in my show at the Artery.

Story that is part of the show: Margaret and Ian Anderson farm land that Ian’s great grandfather settled in the late 19th century. While Ian’s great grandfather raised only sheep and grain the modern ranch is a diversified farming operation growing hay, grain, and cattle as well as sheep. The original sheep on the ranch were mostly Corriedale but today’s 3000 breeding ewes are a blend of Corriedale, Polypay, and Rambouillet breeding. The ewes are bred to Suffolk and Rambouillet rams to produce each year’s lambs. The lambs are raised in adherence to the strict animal handling and environmental sustainability protocols of Niman Ranch, where most of the lambs are marketed. Local sources of Anderson Ranch Lambs are Nature’s Bounty near Vacaville and Chuck’s Custom Slaughter in Dixon.

In September I got the yarn back from the mill and used it for pieces in my show at the Artery.

Story that is part of the show: Margaret and Ian Anderson farm land that Ian’s great grandfather settled in the late 19th century. While Ian’s great grandfather raised only sheep and grain the modern ranch is a diversified farming operation growing hay, grain, and cattle as well as sheep. The original sheep on the ranch were mostly Corriedale but today’s 3000 breeding ewes are a blend of Corriedale, Polypay, and Rambouillet breeding. The ewes are bred to Suffolk and Rambouillet rams to produce each year’s lambs. The lambs are raised in adherence to the strict animal handling and environmental sustainability protocols of Niman Ranch, where most of the lambs are marketed. Local sources of Anderson Ranch Lambs are Nature’s Bounty near Vacaville and Chuck’s Custom Slaughter in Dixon.

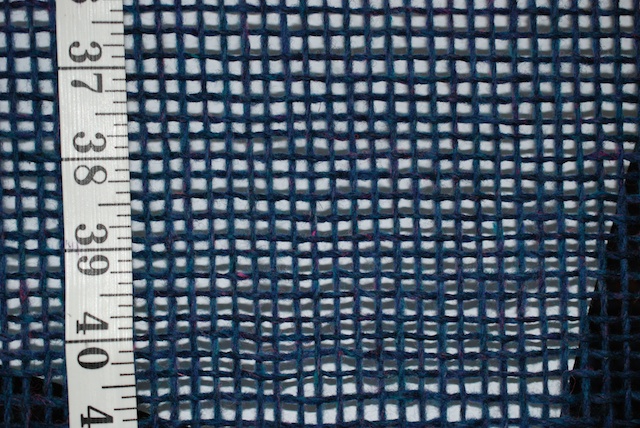

As in many U.S. sheep operations the Anderson Ranch wool is handled as a by-product and is usually baled and sold in bulk. Last spring I watched some of the shearing and brought home about a dozen fleeces. I sorted and pre-washed the wool and shipped 90 pounds to Zeilinger Wool Company in Michigan, one of the few mills in the U.S. that can adequately process fine wools in small quantities. The wool was spun into 54 pounds of 2-ply-sport weight yarn. The fiber averages 20.4 microns. Feel how soft it is for yourself!

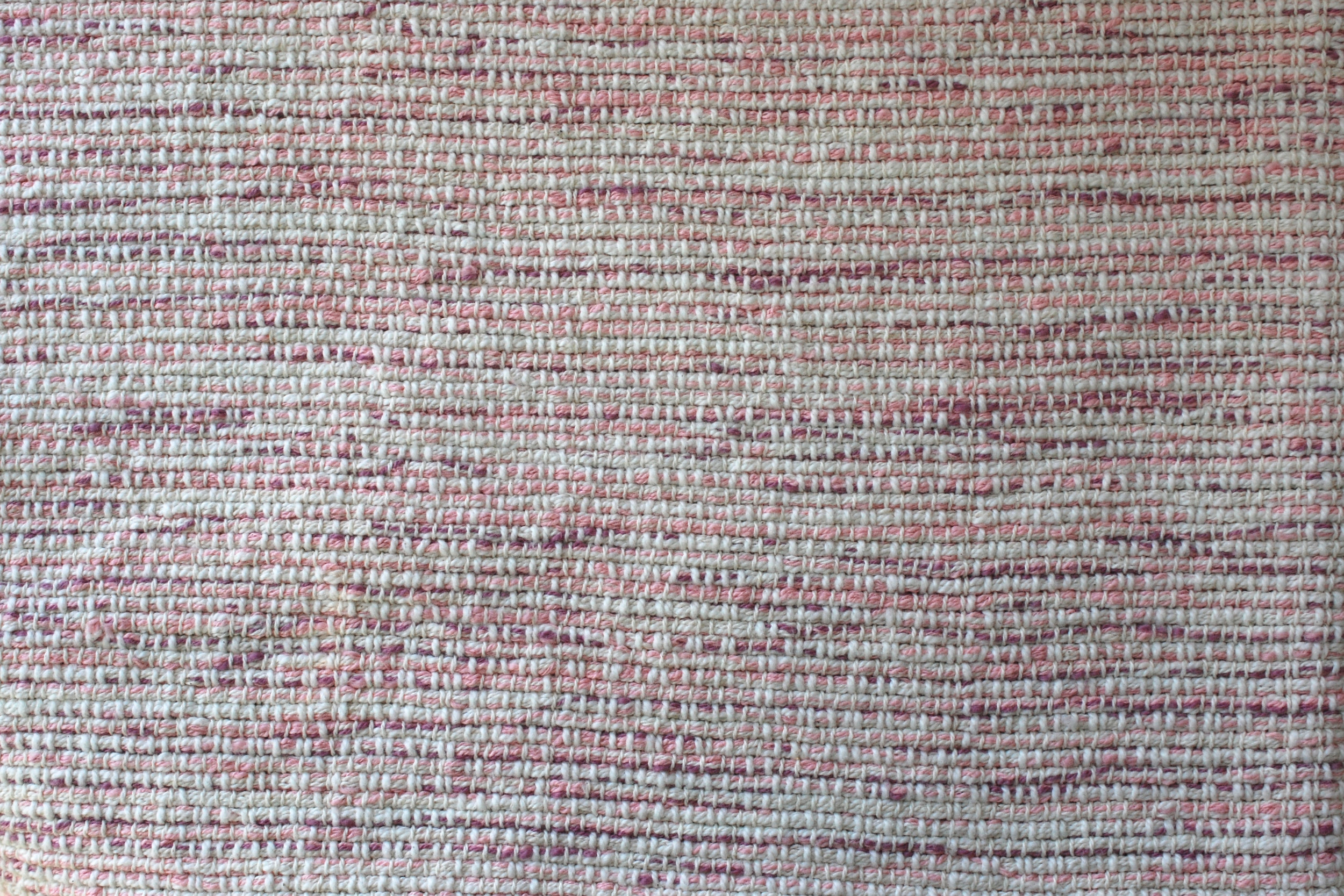

This yarn, like the yarn from the Timm Ranch and processed at Zeilinger's, changes dramatically from it's coned form to skeined yarn or finished piece. I will do another blog post about that because it's so cool to see the changes. This would make a great knitting yarn as well (although I'd skein and wash it first) and it is on my website for sale now.

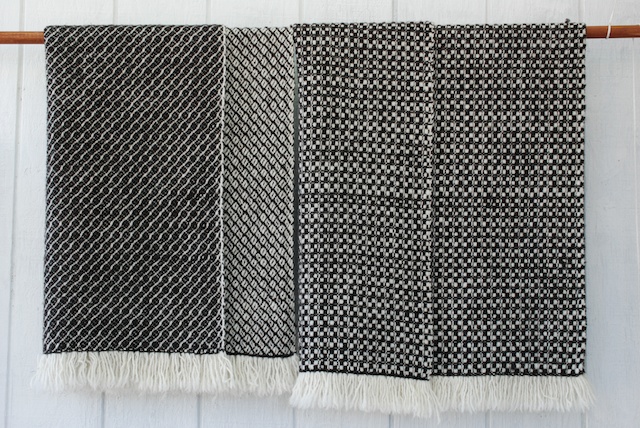

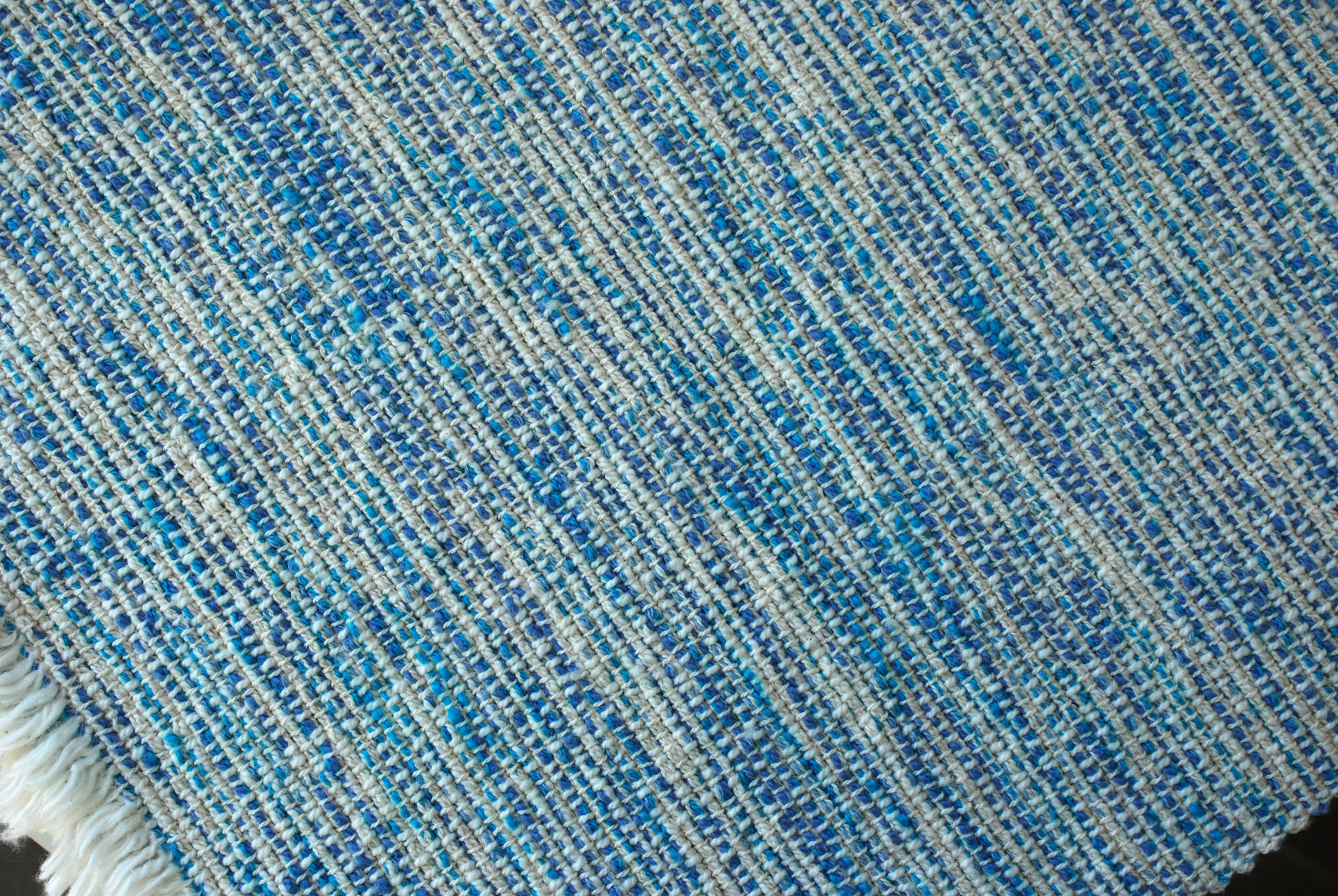

This blanket and the one above it are woven with the same weave structure, but they look different because one has dyed weft. The browns are dyed with black walnut.

This blanket and the one above it are woven with the same weave structure, but they look different because one has dyed weft. The browns are dyed with black walnut.

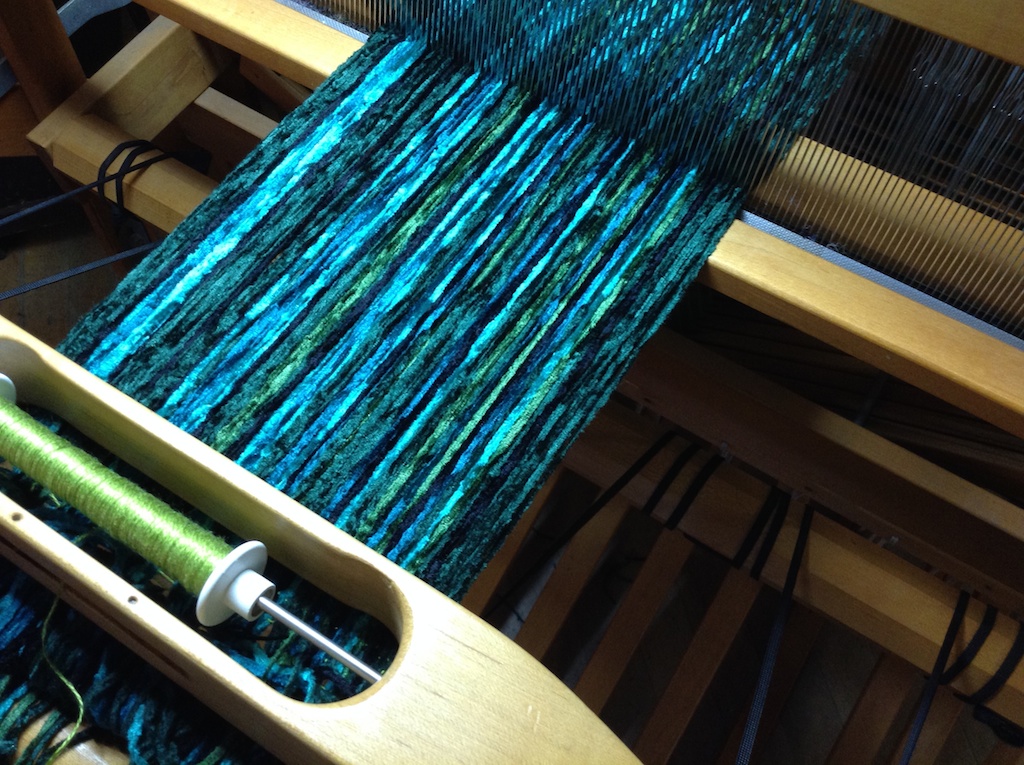

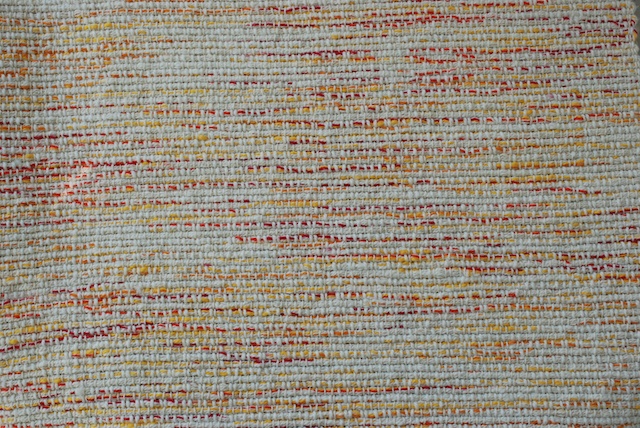

This blanket has weft dyed with osage orange that grows across the road.

This blanket has weft dyed with osage orange that grows across the road. I also wove some scarves.

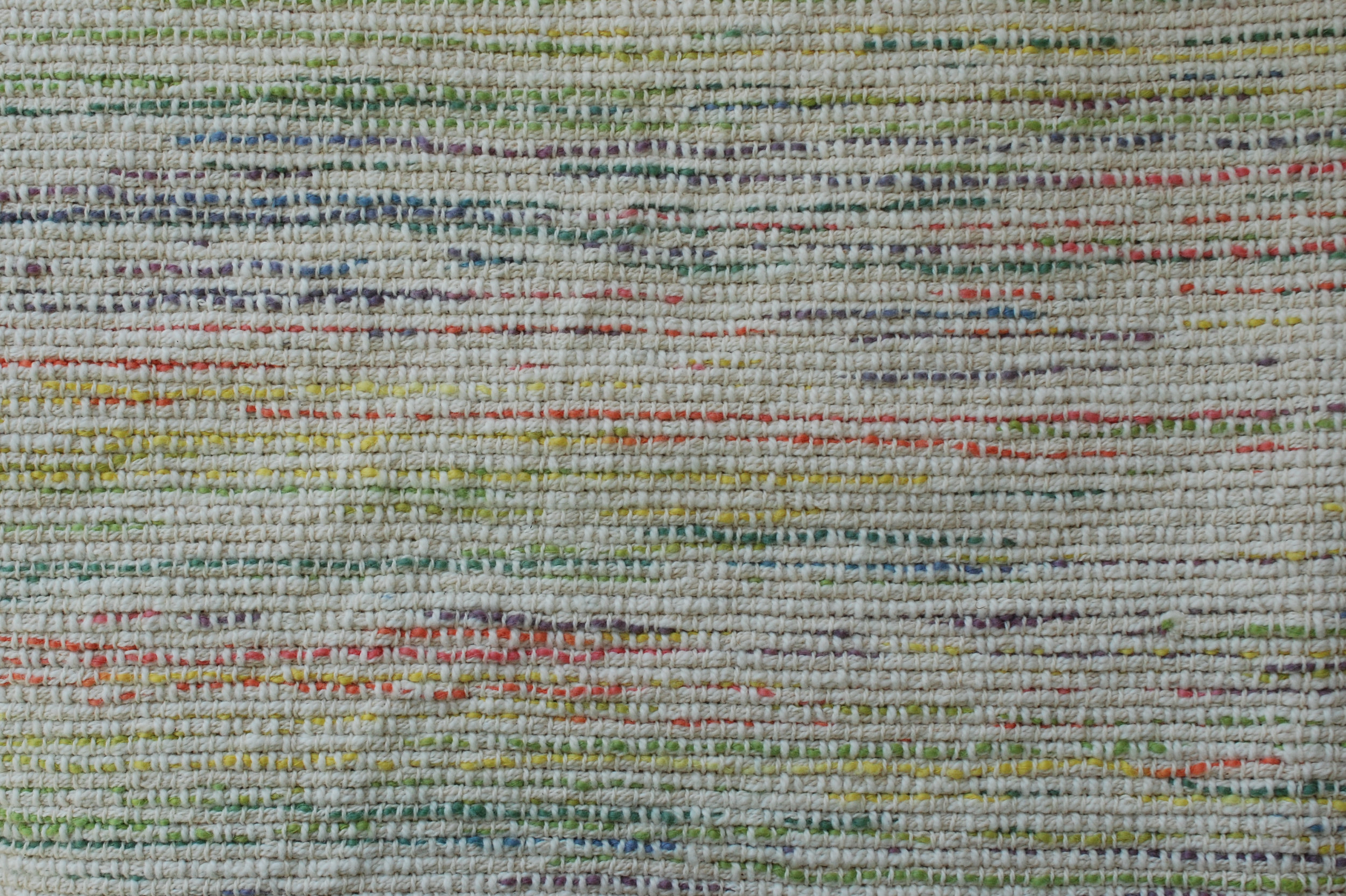

I also wove some scarves.

This is beautiful yarn, very soft and would make great knitted scarves or caps. I look forward to weaving more projects with it. Maybe I'll even be enticed to get out the knitting needles.

This is beautiful yarn, very soft and would make great knitted scarves or caps. I look forward to weaving more projects with it. Maybe I'll even be enticed to get out the knitting needles.

The next two blankets, above and below.

The next two blankets, above and below.

These are East Friesian ewes and their lambs. They graze the hills in Marin County but spend some time in the barn at lambing time and they were in for our

These are East Friesian ewes and their lambs. They graze the hills in Marin County but spend some time in the barn at lambing time and they were in for our

...and this blanket are the same weave structure? The top one uses dark weft and the bottom one uses white.

...and this blanket are the same weave structure? The top one uses dark weft and the bottom one uses white.

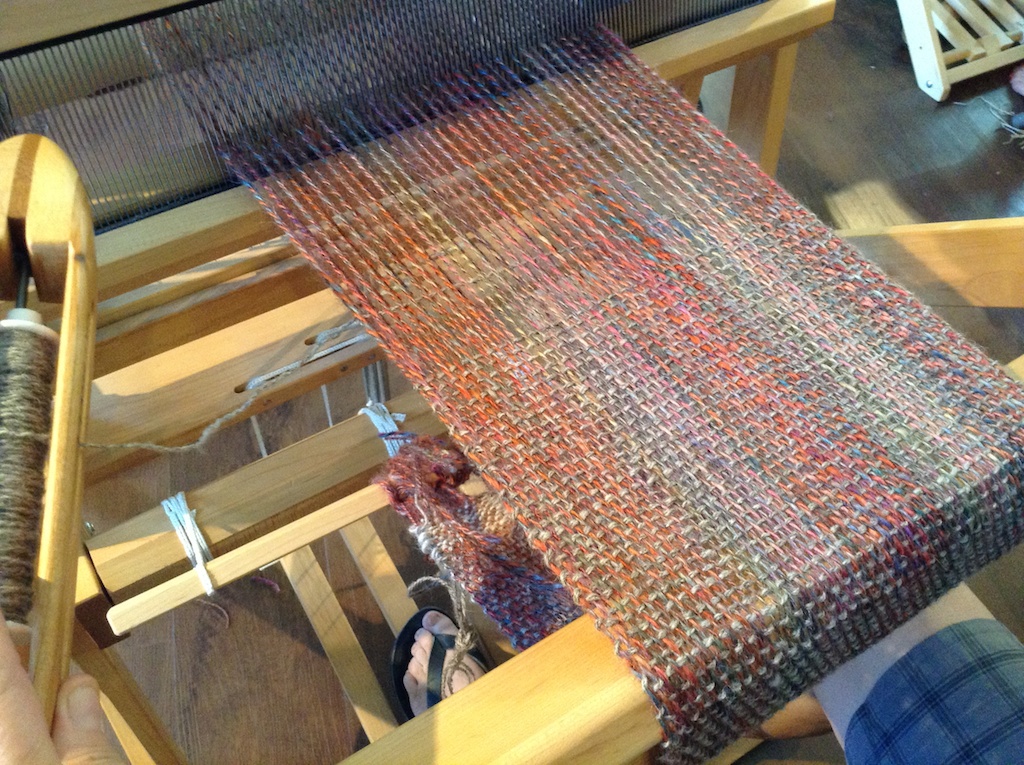

In the first two red, white, and blue blankets I repeated the 8-thread sequence throughout.

In the first two red, white, and blue blankets I repeated the 8-thread sequence throughout. In the next two I designed blocks, sort of plaid like, where the star pattern would show up. Then I decided that there should be something in this collection that was more restful for the eye.

In the next two I designed blocks, sort of plaid like, where the star pattern would show up. Then I decided that there should be something in this collection that was more restful for the eye.

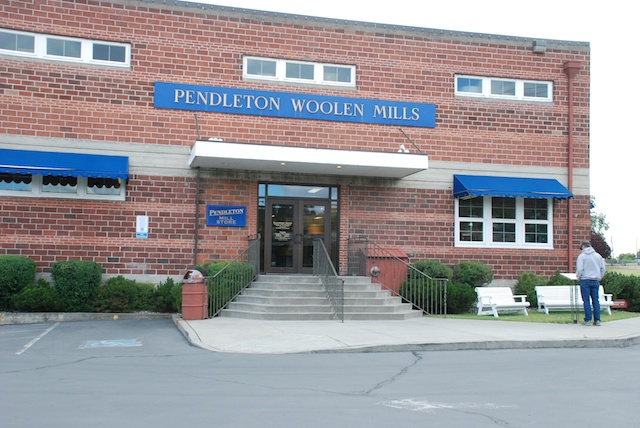

There were about a dozen people there for the tour even at 9 a.m. on a Monday morning. It was interesting to see the workings of the mill but now I have a lot of unanswered questions. We all wore headsets so that we could hear the tour guide over noise of the mill machinery but that meant that there was no opportunity to ask questions while we were walking. And the tour was fast. I would have liked to stop and watch what was going on with each loom. Now that I'm looking at my photos I realize that I have even more questions about what I was seeing. I guess I'll just have to go back!

There were about a dozen people there for the tour even at 9 a.m. on a Monday morning. It was interesting to see the workings of the mill but now I have a lot of unanswered questions. We all wore headsets so that we could hear the tour guide over noise of the mill machinery but that meant that there was no opportunity to ask questions while we were walking. And the tour was fast. I would have liked to stop and watch what was going on with each loom. Now that I'm looking at my photos I realize that I have even more questions about what I was seeing. I guess I'll just have to go back! The Mill uses Rambouillet wool from Oregon and surrounding states and Merino wool from New Zealand and Australia. The wool is scoured in Texas and then comes to Oregon for spinning and weaving. The carding and spinning equipment was on the second floor. That room was quite humid. The guide told us that high humidity lessons the quantity of airborne particles so employees don't have to wear dust masks. Now I wonder if that is the main reason for the humidity or if it makes carding and spinning more efficient (or both). The photo above shows the carding equipment operating behind plexiglass.

The Mill uses Rambouillet wool from Oregon and surrounding states and Merino wool from New Zealand and Australia. The wool is scoured in Texas and then comes to Oregon for spinning and weaving. The carding and spinning equipment was on the second floor. That room was quite humid. The guide told us that high humidity lessons the quantity of airborne particles so employees don't have to wear dust masks. Now I wonder if that is the main reason for the humidity or if it makes carding and spinning more efficient (or both). The photo above shows the carding equipment operating behind plexiglass.

And here is the floor behind the loom.

And here is the floor behind the loom.