Close to Home...Post #13 Felt

/In my fiber pursuits I consider myself first a weaver. That's the predominant technique for the pieces in the show, Close to Home, at the Artery which, by the way is up through December 1. (If you're just tuning in to this blog you can read here about the concept behind the show.) There are over 140 pieces in the show and most are woven. However, one end wall is devoted to felt. Felt, according to the dictionary, is a nonwoven fabric of wool, fur, or hair, matted together by heat, moisture, and great pressure. "Nonwoven fabric" is the key here. Most of the felt in the show is "matted together" by needle felting instead of the heat and moisture part.

Just in case you are picturing me with a felting needle and a pile of wool I want you to know that there is a shortcut--thanks to a friend of mine who has a felting "loom". That's what they call it.

Felt, according to the dictionary, is a nonwoven fabric of wool, fur, or hair, matted together by heat, moisture, and great pressure. "Nonwoven fabric" is the key here. Most of the felt in the show is "matted together" by needle felting instead of the heat and moisture part.

Just in case you are picturing me with a felting needle and a pile of wool I want you to know that there is a shortcut--thanks to a friend of mine who has a felting "loom". That's what they call it. You feed a carded batt of wool in one side (over a light table)...

You feed a carded batt of wool in one side (over a light table)... ...and out the other. The action of hundreds of barbed needles turns the wool into felt.

...and out the other. The action of hundreds of barbed needles turns the wool into felt. I fed each thin batt of wool in once and then layered them together to become a thicker piece.

I fed each thin batt of wool in once and then layered them together to become a thicker piece. The final piece went through the needle loom about a dozen times. For several of my pieces I "wove" strips of roving and applied those to the felt part way through the process. I ended up with lots of placemats, trivets (the thick ones could double as stadium seats), and coasters.

The final piece went through the needle loom about a dozen times. For several of my pieces I "wove" strips of roving and applied those to the felt part way through the process. I ended up with lots of placemats, trivets (the thick ones could double as stadium seats), and coasters.

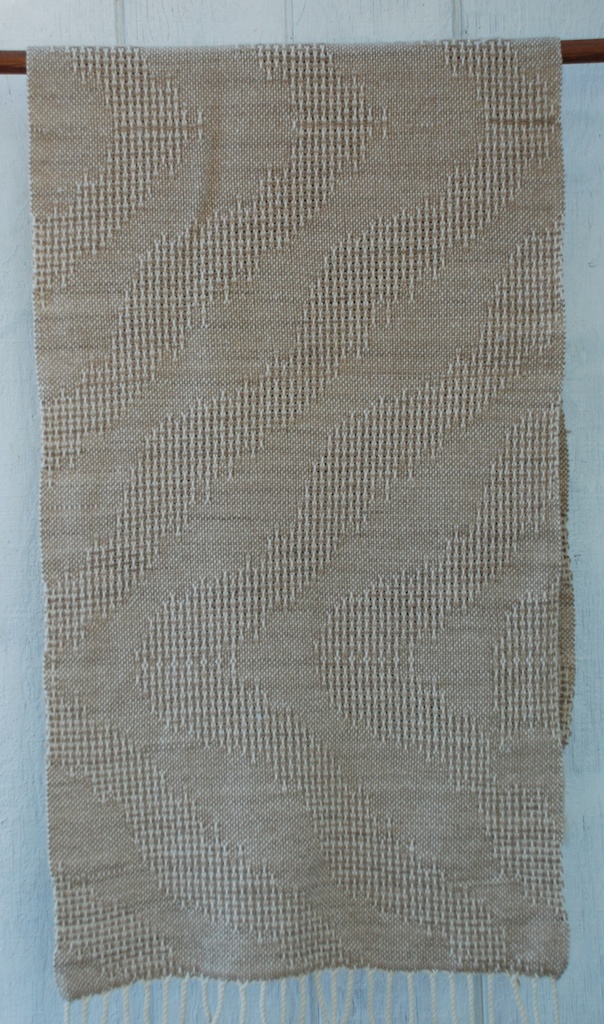

After cutting out the placemats and other items I had felt strips left over. I wove those into wall hangings.

After cutting out the placemats and other items I had felt strips left over. I wove those into wall hangings.

There was one piece of felt that my friends convinced me to leave alone and not cut up. I hung it on the wall at the Artery and it sold as a wall hanging.

There was one piece of felt that my friends convinced me to leave alone and not cut up. I hung it on the wall at the Artery and it sold as a wall hanging. I did use the soap and hot water method in addition to needle felting to create these balls. They are sold as dryer balls (3 in the dryer help reduce drying time and soften clothes), or juggling balls, or cat toys, or therapeutic aids (at least that's why one friend bought some).

I did use the soap and hot water method in addition to needle felting to create these balls. They are sold as dryer balls (3 in the dryer help reduce drying time and soften clothes), or juggling balls, or cat toys, or therapeutic aids (at least that's why one friend bought some).

By the way, the wool for all of the felt items comes from either the Suffolk sheep on the Phillips Farm (see Blog Post #9) or the coarser britch wool of my own Jacob sheep.

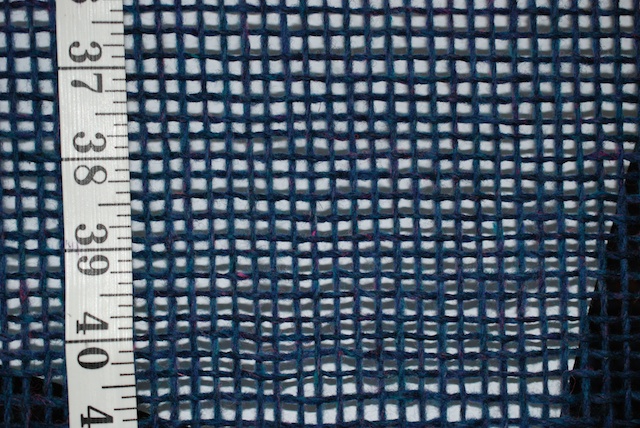

Here is a close-up.

Here is a close-up.

This is one of only two yarns in this show that are not grown in Solano or Marin Counties but I included it because of the variety of colors, naturally dyed, and the quality of the yarn, and it is grown in the Pacific Northwest, which is Closer to Home than many places where wool is grown.

This is one of only two yarns in this show that are not grown in Solano or Marin Counties but I included it because of the variety of colors, naturally dyed, and the quality of the yarn, and it is grown in the Pacific Northwest, which is Closer to Home than many places where wool is grown.

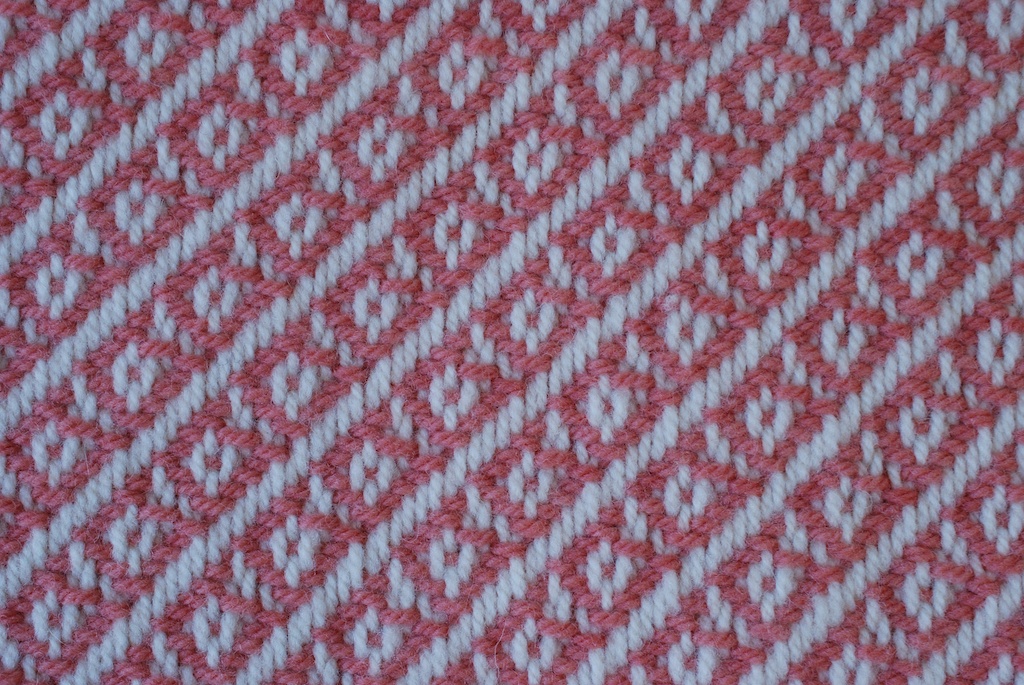

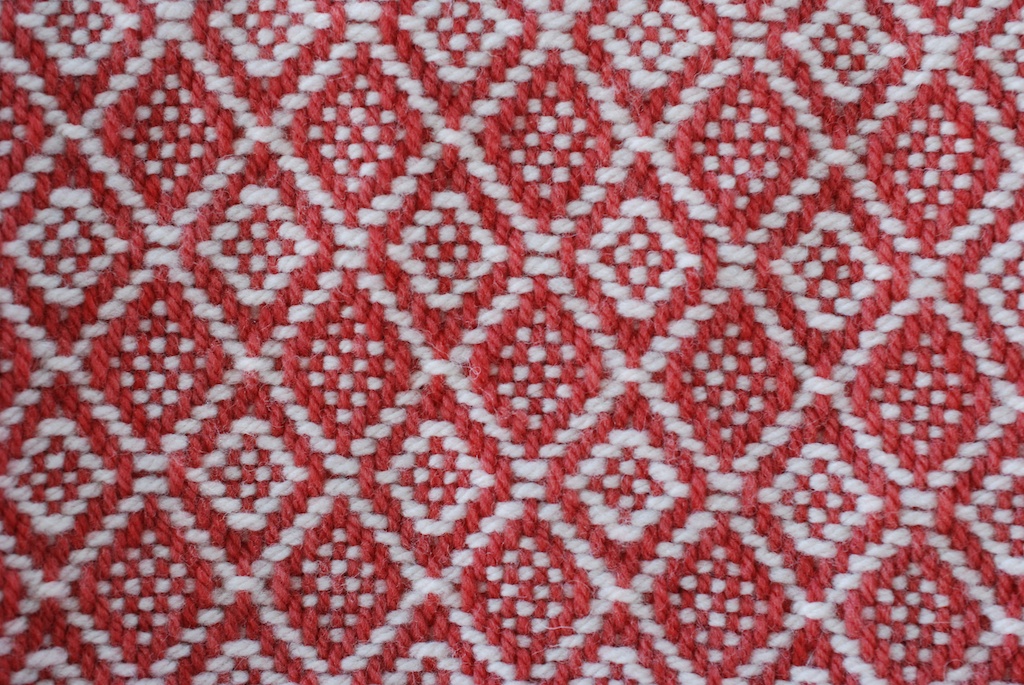

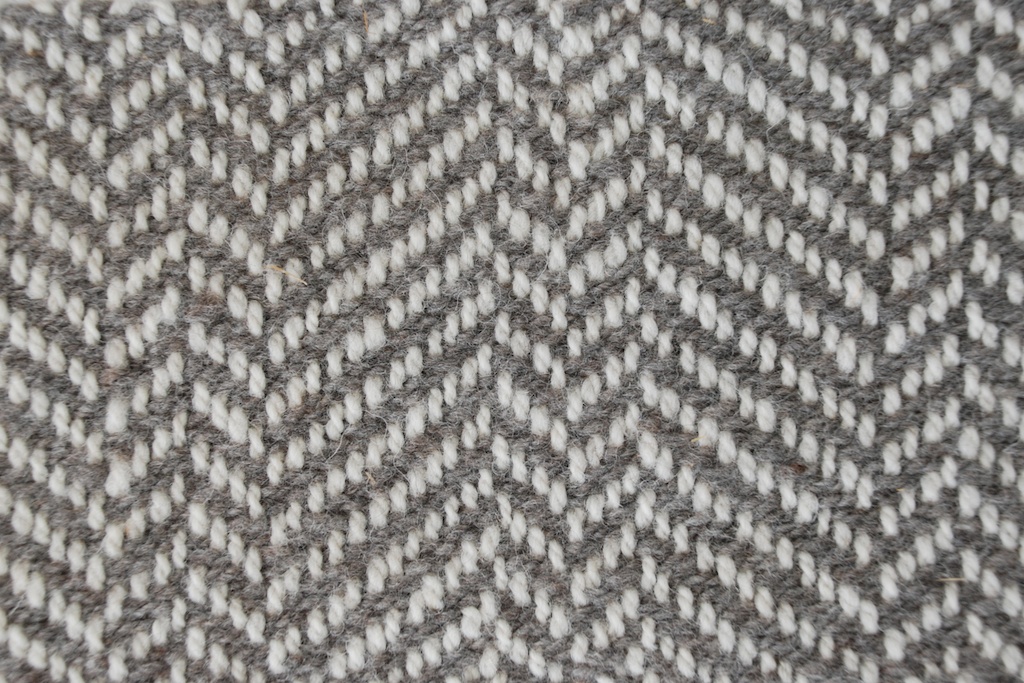

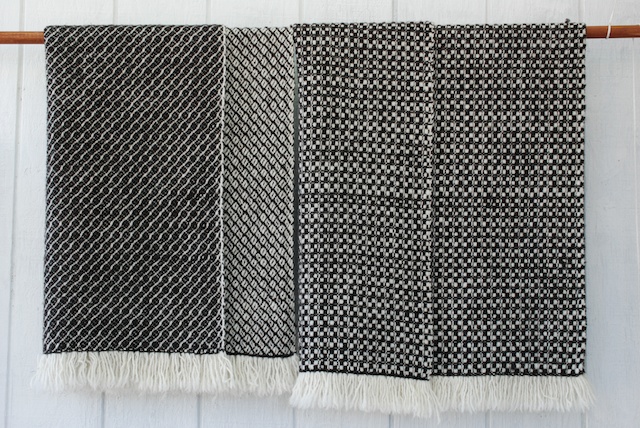

That means that each of the blankets above was woven on the same warp threading in white yarn, but the patterns change by varying the treading and, of course, the color of the weft.

That means that each of the blankets above was woven on the same warp threading in white yarn, but the patterns change by varying the treading and, of course, the color of the weft.

At the end of the warp I just wove in white instead of making it plaid and then I felted the fabric. That made great fabric for pillows.

At the end of the warp I just wove in white instead of making it plaid and then I felted the fabric. That made great fabric for pillows.

This is a scarf from more of the left-over yarn.

This is a scarf from more of the left-over yarn. In September I got the yarn back from the mill and used it for pieces in my show at

In September I got the yarn back from the mill and used it for pieces in my show at

The next two blankets, above and below.

The next two blankets, above and below.

These are East Friesian ewes and their lambs. They graze the hills in Marin County but spend some time in the barn at lambing time and they were in for our

These are East Friesian ewes and their lambs. They graze the hills in Marin County but spend some time in the barn at lambing time and they were in for our

...and this blanket are the same weave structure? The top one uses dark weft and the bottom one uses white.

...and this blanket are the same weave structure? The top one uses dark weft and the bottom one uses white.

In the first two red, white, and blue blankets I repeated the 8-thread sequence throughout.

In the first two red, white, and blue blankets I repeated the 8-thread sequence throughout. In the next two I designed blocks, sort of plaid like, where the star pattern would show up. Then I decided that there should be something in this collection that was more restful for the eye.

In the next two I designed blocks, sort of plaid like, where the star pattern would show up. Then I decided that there should be something in this collection that was more restful for the eye.

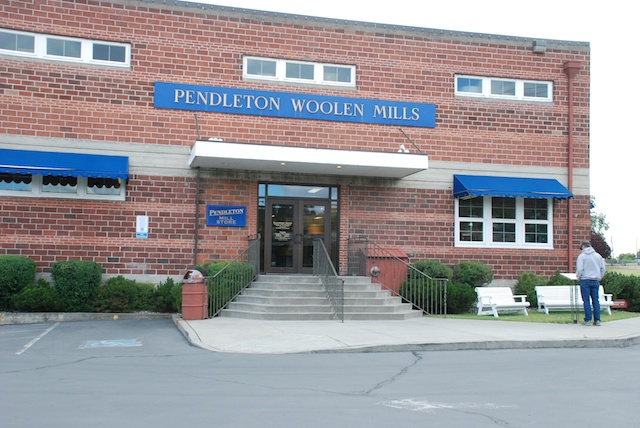

There were about a dozen people there for the tour even at 9 a.m. on a Monday morning. It was interesting to see the workings of the mill but now I have a lot of unanswered questions. We all wore headsets so that we could hear the tour guide over noise of the mill machinery but that meant that there was no opportunity to ask questions while we were walking. And the tour was fast. I would have liked to stop and watch what was going on with each loom. Now that I'm looking at my photos I realize that I have even more questions about what I was seeing. I guess I'll just have to go back!

There were about a dozen people there for the tour even at 9 a.m. on a Monday morning. It was interesting to see the workings of the mill but now I have a lot of unanswered questions. We all wore headsets so that we could hear the tour guide over noise of the mill machinery but that meant that there was no opportunity to ask questions while we were walking. And the tour was fast. I would have liked to stop and watch what was going on with each loom. Now that I'm looking at my photos I realize that I have even more questions about what I was seeing. I guess I'll just have to go back! The Mill uses Rambouillet wool from Oregon and surrounding states and Merino wool from New Zealand and Australia. The wool is scoured in Texas and then comes to Oregon for spinning and weaving. The carding and spinning equipment was on the second floor. That room was quite humid. The guide told us that high humidity lessons the quantity of airborne particles so employees don't have to wear dust masks. Now I wonder if that is the main reason for the humidity or if it makes carding and spinning more efficient (or both). The photo above shows the carding equipment operating behind plexiglass.

The Mill uses Rambouillet wool from Oregon and surrounding states and Merino wool from New Zealand and Australia. The wool is scoured in Texas and then comes to Oregon for spinning and weaving. The carding and spinning equipment was on the second floor. That room was quite humid. The guide told us that high humidity lessons the quantity of airborne particles so employees don't have to wear dust masks. Now I wonder if that is the main reason for the humidity or if it makes carding and spinning more efficient (or both). The photo above shows the carding equipment operating behind plexiglass.

The sheep are gathered at the back of a trailer that is hauled from ranch to ranch with all the gear. They go up the chute with the encouragement of...

The sheep are gathered at the back of a trailer that is hauled from ranch to ranch with all the gear. They go up the chute with the encouragement of...

Here is a view from the other end of the trailer. That sheep in front hangs out for awhile in that position because the other sheep are more likely to go forward if they see a sheep in front of them. Notice how the sheep walk on a raised alleyway while the freshly shorn fleeces are shoved out of the trailer below them.

Here is a view from the other end of the trailer. That sheep in front hangs out for awhile in that position because the other sheep are more likely to go forward if they see a sheep in front of them. Notice how the sheep walk on a raised alleyway while the freshly shorn fleeces are shoved out of the trailer below them.