Lambtown Last Weekend

/It already feels as though Lambtown was a long time ago but I wanted to share some of the photos.

Lambtown was the first weekend of October.

There is a lot to see at Lambtown and it was great to be in person after a couple of years of trying this virtually. I didn’t take many photos because I was mostly in my booth. These photos are from a few brief excursions to check on the Sheep-to-Shawl progress.

I’ve always liked this sheep which used to stand along the road outside the fairgrounds.

I provided items for the Fibershed Coop booth in the vendor hall.

This is two views (above and below) of my booth in the vendor hall.

This straw bale maze complete with pool noodle “ponies” looked like great fun for little kids.

Farm Club members took part in Lambtown. Siobhan taught her first class on spinning with a distaff. There was so much demand that she taught an extra session.

Janelle took Siobhan’s class, learning how to follow in the footsteps of someone depicted in this wood carving that is a family memento.

Dan was asked if he would put in a couple of hours driving the tractor around the fairgrounds to deliver people to and from events.

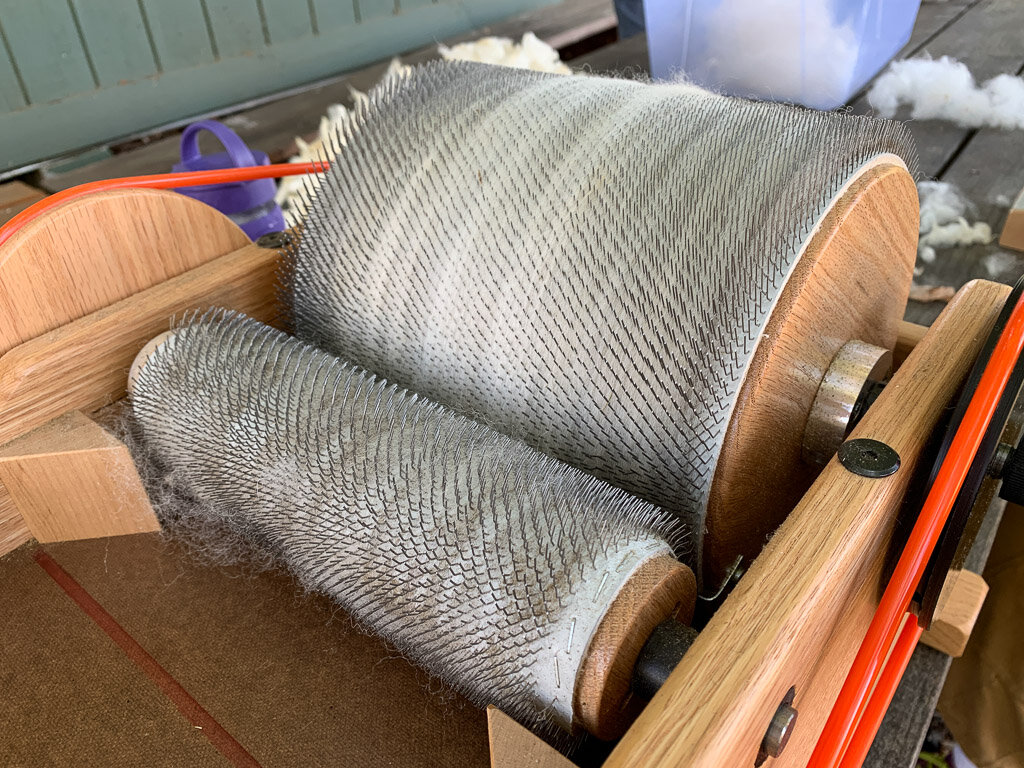

The Farm Club fielded a Sheep-to-shawl team. At the last minute a couple of people had to drop out but others (including a non-FC member) came to the rescue and filled in.

I am grateful to the team for pulling this all together late in the game and doing it all without asking me for help. I did provide fiber and yarn and the loom, but that was the easy part. They met , mostly virtually, to do all the planning.

Ryan (spinning here) dyed the warp yarn a gorgeous blue with indigo

Reba planned the project, warped the loom and did the weaving. The shawl was very pretty, but wasn’t judged. The team wisely decided to not cut it off too early just to make the timed deadline, but to finish the weaving so that shawl would be the correct size. Reba finished the weaving later that evening.

This shawl is not black and white, but blue and white. I just can’t make it show up that way. Good job, team!