Virtual Sheep-to-Shawl Contest

/Like everything else in our lives this year Lambtown, our local fiber fair, has become virtual. The festival will be held (virtually) on it’s regular dates—the first weekend of October. The sheep-to-shawl contest was changed to try it in a virtual format. Normally in a Sheep-to-Shawl contest teams of 6 or 7 people gather on one day and in 4 or 5 hours, depending on the contest rules, prepare and spin the wool and weave a shawl that is judged at the end of the contest. The loom is warped ahead of time and teams have procurred and washed their fiber, but no other work has been done until the contest starts.

How does a virtual contest work? My friends who manage Lambtown and created the first ever (as far as we know) virtual sheep-to-shawl contest decided that if in a regular contest there are 7 people on a team and they have four hours to complete the work then the same time should be allowed vitually. Seven people worked for 4 hours means 28 people hours were used. They decided that teams could be from 2 to 7 members and they could choose to compete all together on one day or separately over several days—after all the whole reason for this is because of Coronovirus requirements for social distancing. Zoom meetings were set up for the weekends in August and September and all work needed to be on Zoom—teams could choose which days to work and how many people would gather. Everyone who put in time had to record their time in half hour increments and each team had a maximum of 28 hours to complete the shawl.

Last year the Meridian Jacobs Farm Club put together a team and competed at Black Sheep Gathering in Oregon in July and at Lambtown in October. I couldn’t be on the team because at BSG I was showing sheep and at Lambtown I was a vendor. This year I am a vendor at Lambtown but, being virtual, there was no conflict with dates.

There were six of us on the team and we hadn’t planned on this ahead of time. So the first task was to figure out what fiber to use. Jacob wool, of course, but I didn’t have any left from the last shearing. Some of the Farm Club members had fiber left from previous years (imagine that, FC members with stashes of fibre!) so our weft fiber would be a combination of contributions from Jacob sheep. We decided to use white because I wanted to weave a pattern that I’ve been doing lately and it would best show up with a white weft on a dyed warp. I warped the loom with some of the Timm Ranch yarn that I dyed using coreopsis. I wove a couple of sample shawls to get an idea of the time to allow for the weaving (about 3 hours).

This was our first day back on August 8. One of our members couldn’t come on this day so there were five of us prepping fiber. We worked under the trees near the shop and spaced out over two picnic tables to maintain our social distancing.

The first step was to open up the wool locks by “lock-popping”.

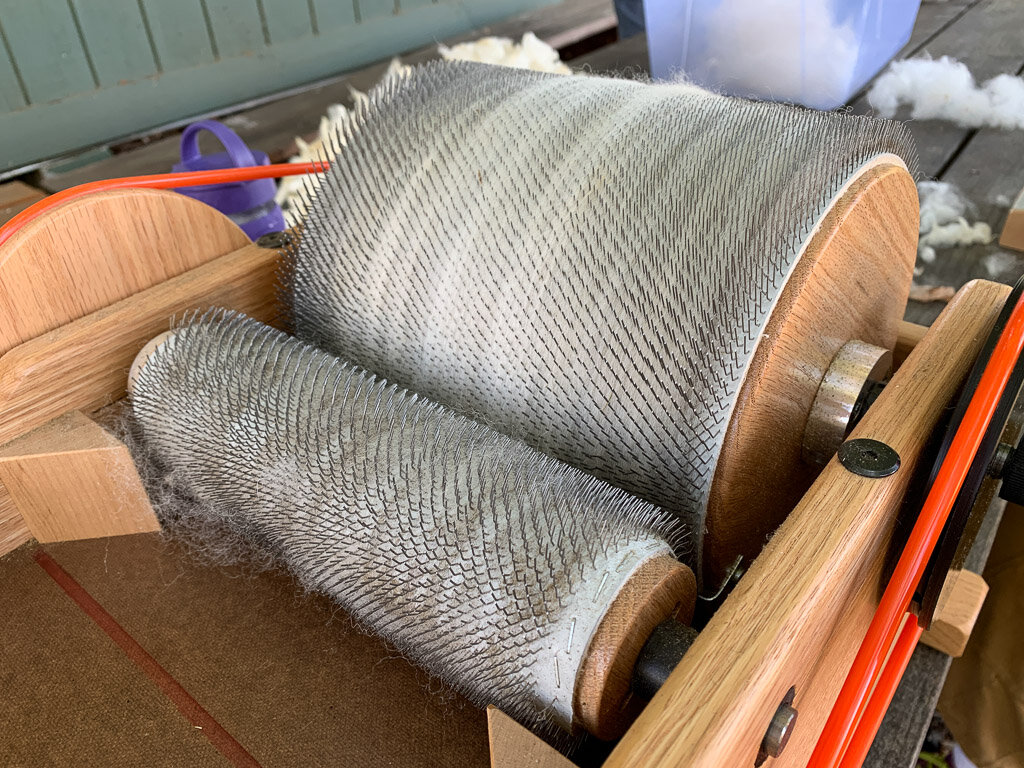

That is a term that Clemes and Clemes used when they developed this handy tool. Then we carded the popped locks.

This is an electric drum carder but the rules of the sheep-to-shawl contest prohibit using electric carders so we attached the handle to this one and hand cranked.

The rules also included showing all work on Zoom. We set up the iPad to view all the team members. Some of the team started spinning but I didn’t get more photos. The missing team member stopped by to pick up the bobbins from the day’s work. She did her own Zoom session a week or two later while she plied the yarn—that would give us some yarn so I could get started with weaving right away at our next session.

We worked until about 1 that day and then Dan and I had to meet a livestock hauler in Sacramento to deliver sheep that would be going to buyers in the midwest.

This is the trailer that the sheep were to go in. This is the same brand as our new trailer (on the left in this photo) but this one is huge. The livestock are in the silver part and the tack room/living quarters take up the whole front of this one. It’s quite the rig!

Here is the trailer interior showing some of the travel companions. They included goats and little pigs.

Back to the Sheep-to-Shawl contest.

All our team members were able to gather yesterday (September 6) and our plan was to do all the work necessary to complete the shawl. We had 13 hours left of the 28 total hours we could use for his. So the plan was that i would start weaving while the others spun and plied with a little more fiber prep thrown in. The spinners would go “off the clock” when it was determined that there was enough yarn to finish the shawl.

We set up two devices. My ipad showed the spinners sitting to the south and a phone was aimed at my loom and one person who was still prepping fiber at the picnic table.

It is shady under the trees, but we set up canopies to be more fully protected from the sun. It was predicted to get to 110 by later in the day and it was hot even in the morning. In addition it was another smoky day. The air quality had improved over the last couple of days but this day it was dramatically worse again—we could smell smoke and there was ash on the tables we had just cleaned.

This was my view all morning. I was under a time deadline so I didn’t take very many photos. We started at 10 and I wove until 11:30 when I ran out of weft yarn and had to let the spinners catch up. Then I started weaving again at noon. I finished weaving about 12:30 and then we cut off the shawl and two of us worked on twisting the fringe. We finished with minutes to spare.

Now I need to pack this up and mail it off. It will be judged on the Lambtown weekend in a virtual venue.

Thanks to this great group of friends for coming together for this event and for your support of me and the farm throughout what has been a trying year.