To Beat or to Nudge and What About Wet Finishing?

/I taught a short weaving workshop today as part of Sacramento Weavers’ Mini-Workshop meeting. The topic was Clasped Warp and all seven participants finished warping their rigid heddle looms. The time didn’t allow for weaving, but the goal of the workshop was to teach this warping technique, and everyone knew that they’d have to do the weaving later at home.

This blog post is going to serve as a follow-up to the workshop after I fielded a question from one of the participants about why the warp isn’t visible after she started weaving. The point of a clasped warp is that you will see that design in the finished piece. I can tell already that this blog post is going to be too long and I’ll do another with clasped warp photos. This post is about how different cloth looks on the loom and after wet finishing. And it is about Beat.

Blue and white fabric on the loom. Each of the bands of color is 8 threads and you can see that the bands are just under an inch. That means the weft was “beat” at 8 picks per inch (8 ppi).

After washing those bands are closer to 3/4” and the weft picks are more like 10 ppi. That is because the yarns are no longer under the tension that they were on the loom and they have relaxed. Wet finishing (soaking in water) helps the yarns to bloom and also lessons some of the space between yarns.

We talk about “beating” the weft and we use the “beater” that is part of the loom. One of the definitions of beat in Webster's Dictionary is “to strike directly against forcefully and repeatedly”. In terms of weaving that might work well if I was making a saddle blanket or a rug or another dense fabric. But if I want my fabric to have the drape of a scarf or shawl, especially when using a stretchy wool, then maybe I should “nudge” the weft pick. Webster’s definition of “nudge”: “To touch or push gently”.

Its difficult for beginning weavers to realize how lightly one can beat (nudge) the weft yarn and have a successful project. However, each yarn is different and what works for one may not work for another. That’s why sampling is a good thing when you start with an unknown yarn. The lower sample above is woven with the local Timm Ranch wool yarn sett at 8 epi (ends/inch).

This is how it looks after wet finishing. I have worked with this yarn extensively and know to expect this outcome. So I sett the yarn appropriately.

This shows the difference in the yarn before and after wetting. The fiber doesn’t shrink, but the yarn relaxes and “blooms”. This is important to know when planning a project.

This shows the yarn in skeins. The one on the right has been soaked in water and allowed to dry naturally. This is off the topic of “beat” or “nudge” but it all affects the outcome of the project.

This warp is a mix of Jacob yarn and Timm Ranch yarn dyed with black walnut and mushrooms. It is sett at 6 epi. Notice how it looks loosely woven.

The warp was long enough for several shawls. The photo shows an unfinished and a finished piece. I wet finish large pieces in my old top loading washing machine. I put the fabric in hot water and detergent, agitate for usually 2 to 3 minutes, and then spin out the water. I remove the fabric to fill the washing machine with rinse water and then soak the piece briefly without agitating. I use the spin cycle to remove the water.

Here are a few more before and after examples of pieces I recently wove for my Shades of Black and White show at The Artery.

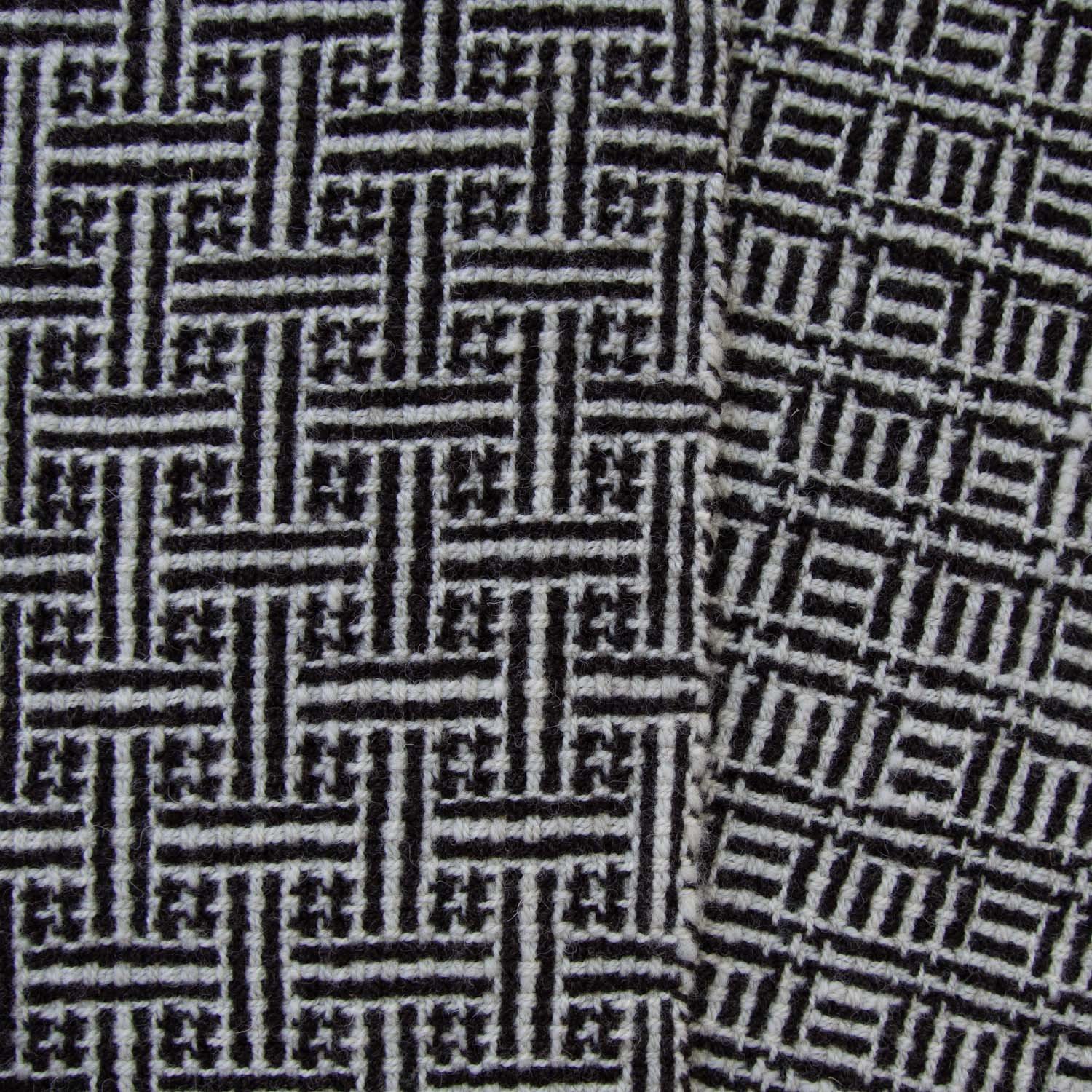

This is Jacob yarn sett at 8 epi. It’s important to nudge those yarns at 8 ppi to maintain the balance of the squares. If I beat harder I’d lose that pattern.

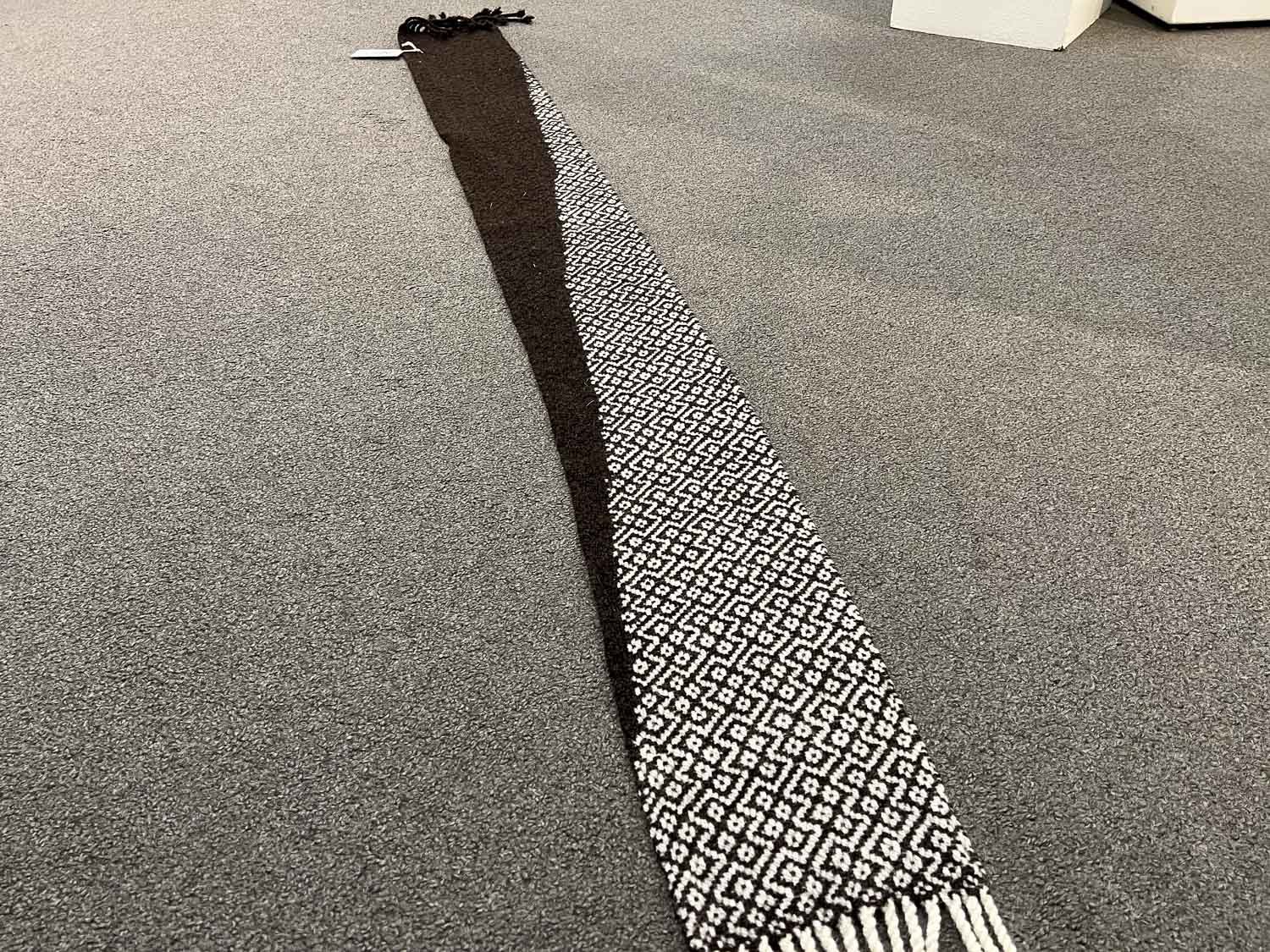

The finished scarf.

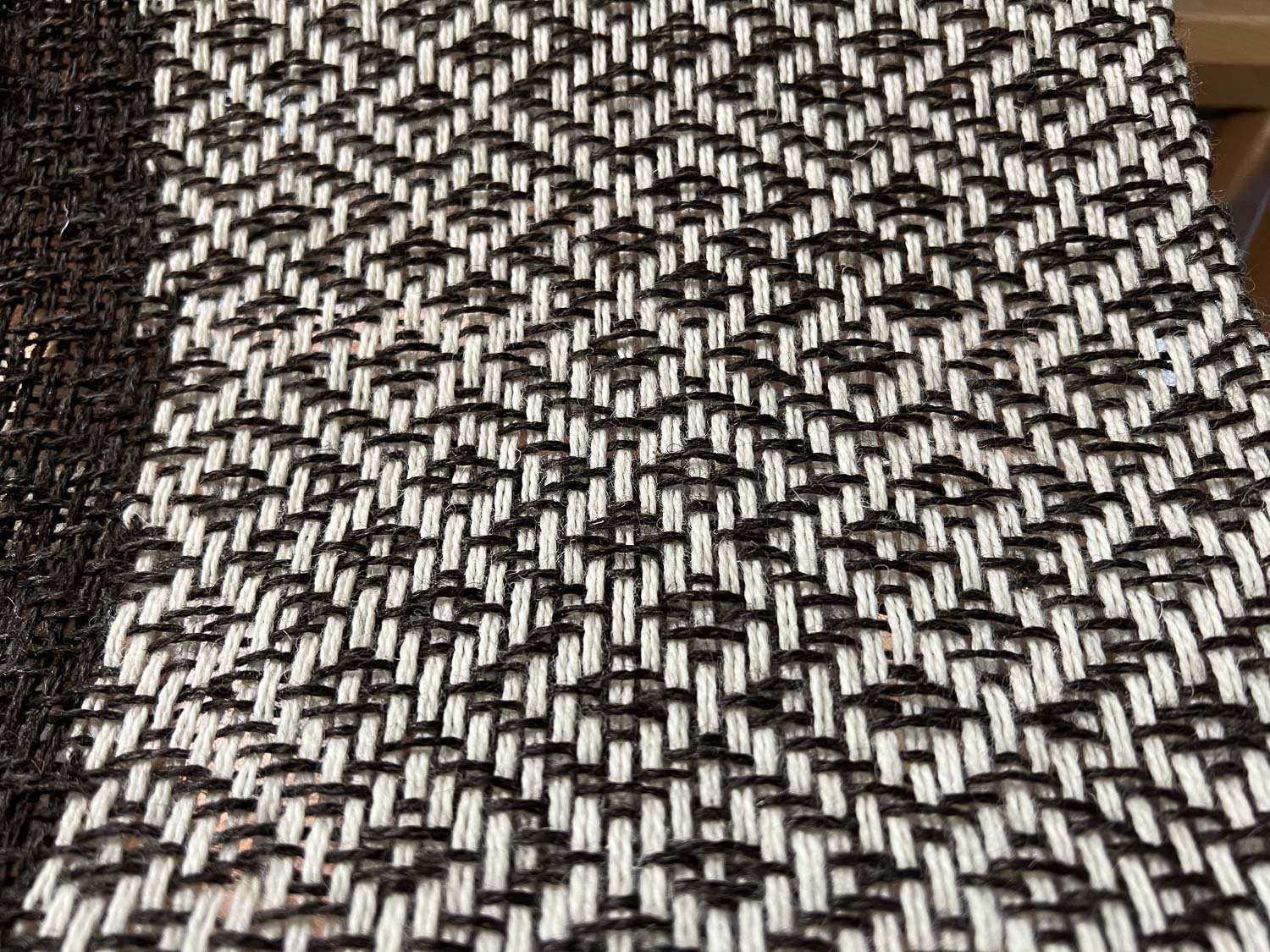

Close up of the pinwheel fabric.

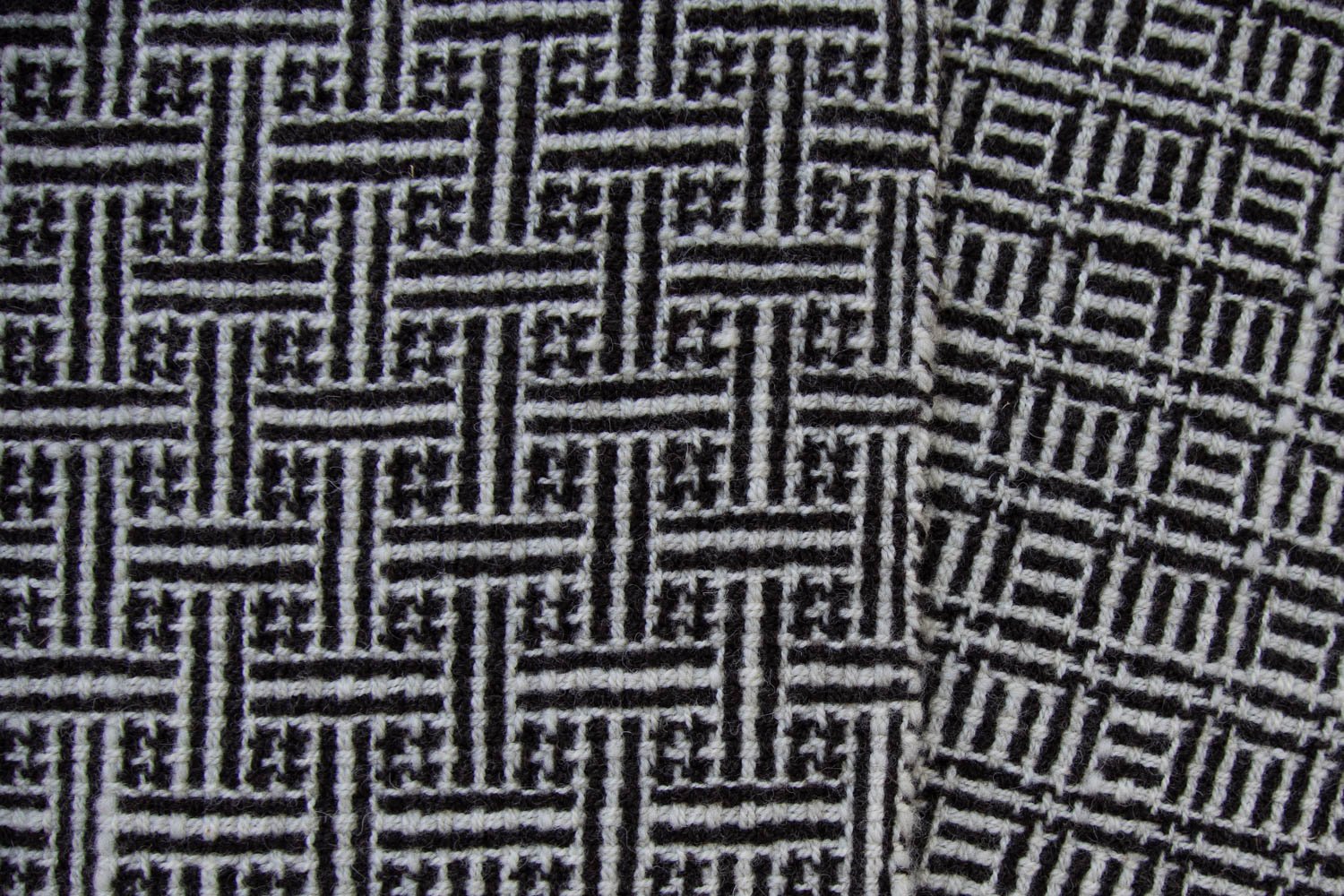

This is another shawl using Jacob yarn. It was sett at 8 epi. Beat is 8 ppi.

This is after wet finishing (3 minutes of agitation). The fabric is thicker because the yarns have bloomed. It has a lot of drape and bounce. My notes show that draw-in (widthwise) and take-up (lengthwise) and shrinkage was 22%. So this started out at 25” wide on the loom and finished at 19.5”.

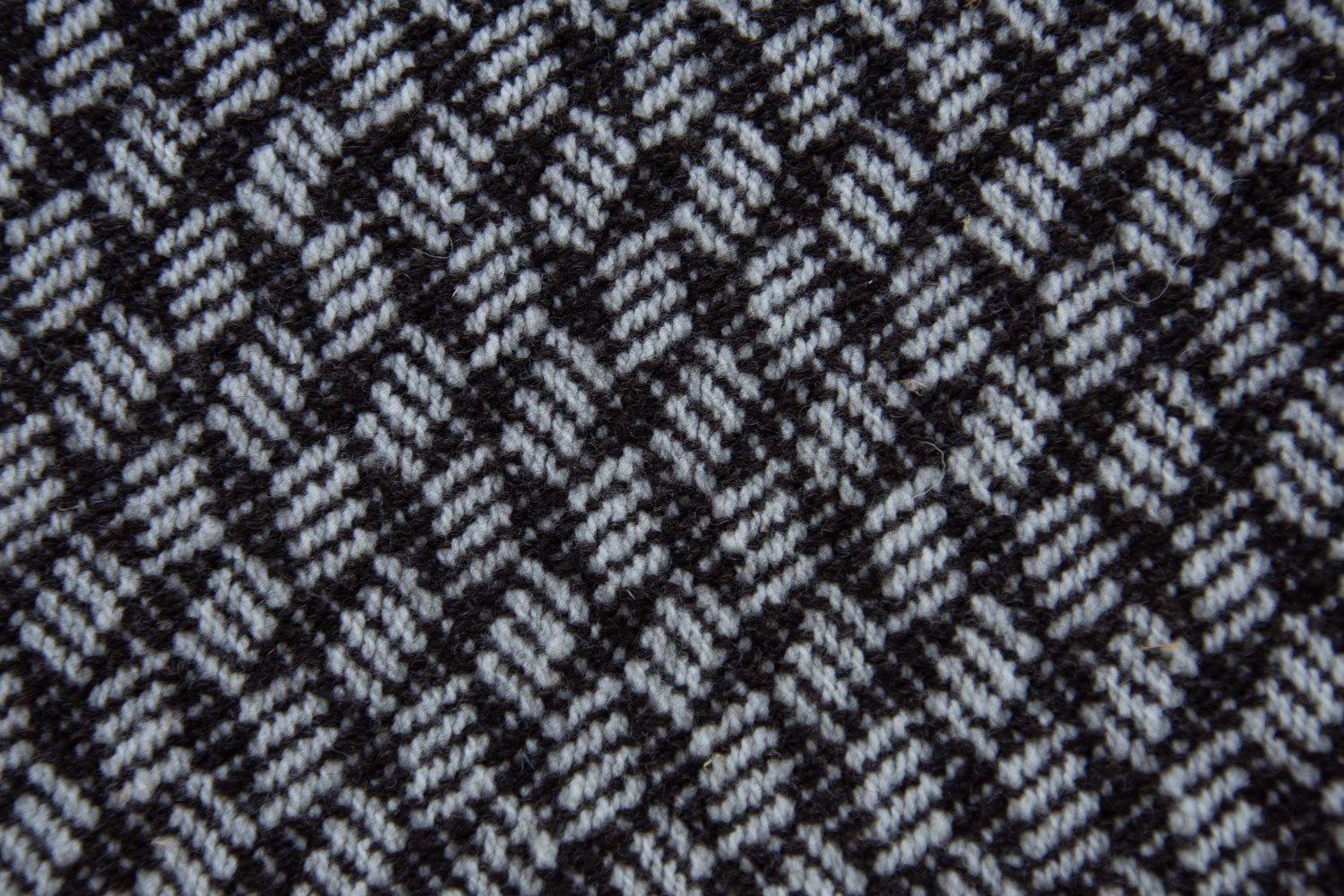

Here is another using Jacob wool. The details are similar to the previous one—8 epi and 25” wide on the loom. This design relies on alternating two dark threads and two light threads in warp and weft.

The shawl is 19” wide after finishing. This pattern behaved differently with 25% change widthwise and 18” lengthwise.

Here is a close-up of the fabric. I love the difference in the two sides of the fabric.

This is the last piece that I wove for the show. It uses the clasped warp technique, but on the floor loom instead of a rigid heddle.

I forgot to get a photo of this one before I set up the show so I took a quick shot at the Artery.