Weaving on the Go

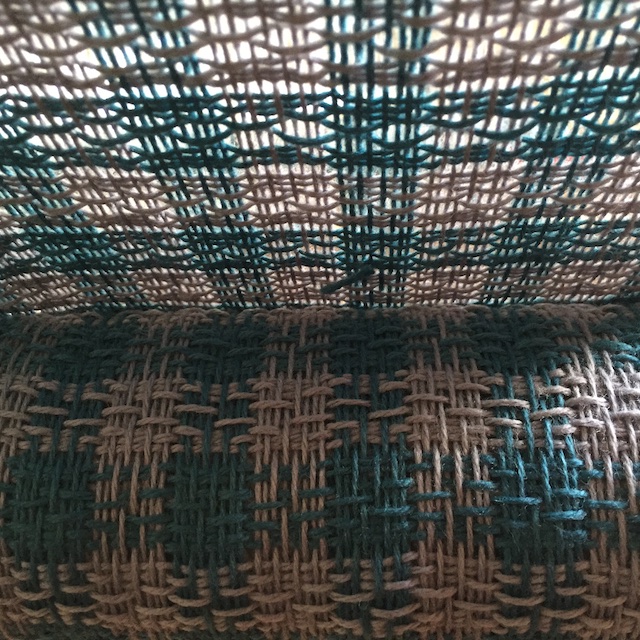

/I have been gone for a few days but took a rigid heddle loom with me. What an easy way to enjoy weaving away from home.  These are scarves in 3/2 cotton (which I have in the shop but isn't on my website). A pressing when I get home will give them a more finished look.

These are scarves in 3/2 cotton (which I have in the shop but isn't on my website). A pressing when I get home will give them a more finished look. A wool scarf in Jaggerspun Maine Line wool. These three scarves are samples for a couple of classes, the new Color on the Loom (in July) and Learn to Weave on the Rigid Heddle Loom.

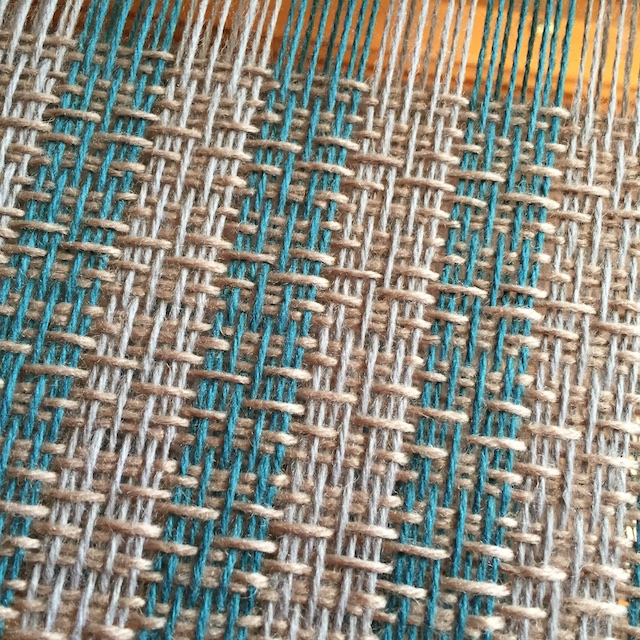

The following photos are of recent weaving in the shop.

A wool scarf in Jaggerspun Maine Line wool. These three scarves are samples for a couple of classes, the new Color on the Loom (in July) and Learn to Weave on the Rigid Heddle Loom.

The following photos are of recent weaving in the shop. Jacob scarves with detail below.

Jacob scarves with detail below.

Another warp of Jacob scarves.

Another warp of Jacob scarves.

I had the idea of weaving a wool checkerboard to sell through the Fibershed Marketplace and at the Artery. But first I used cotton--the same 3/2 cotton as the scarves in the first photo.

But first I used cotton--the same 3/2 cotton as the scarves in the first photo.

Using the the last of the warp I experimented with different weaving order. I think its interesting that at different angles it looks as though I used other colors but all the yarn here is black and white. By the way, I know that checkerboards are traditionally red and black but, oh well...

Using the the last of the warp I experimented with different weaving order. I think its interesting that at different angles it looks as though I used other colors but all the yarn here is black and white. By the way, I know that checkerboards are traditionally red and black but, oh well...

I don't have a photo of the wool checkerboards yet but here are the checkers I made from horns. What do you think of the oblong shape?

In this photo the checkers haven't been finished.

In this photo the checkers haven't been finished. In other weaving, this is the latest issue of Handwoven with my Yarn Lab article in which I compared fulling and felting of Imperial Yarn Company's Columbia and Erin yarns.

In other weaving, this is the latest issue of Handwoven with my Yarn Lab article in which I compared fulling and felting of Imperial Yarn Company's Columbia and Erin yarns.