Shearing Day

/Shearing Day was yesterday. What a wonderful time. Farm Club came through (as always) and handled all the various tasks of the day. (Except for Rusty's job, which he describes in his blog so I am not duplicating his photos here). I am grateful to the great shearer who has come for the last few years. He does a wonderful job--the sheep look good and the fleeces look good. John is so fast that he finished with 64 sheep in about 2 1/2 hours.

One important job is making sure that the shearer always has a sheep to shear as soon as he finishes with the last one.

One important job is making sure that the shearer always has a sheep to shear as soon as he finishes with the last one.

I took some videos too but it will take me awhile to get those edited. You can sign up on the Meridian Jacobs YouTube Channel and see them when they are ready.

I took some videos too but it will take me awhile to get those edited. You can sign up on the Meridian Jacobs YouTube Channel and see them when they are ready.

This is the BFL/Jacob crossbred ewe. I probably could have started a bidding war on her fleece, but I'm keeping it.

This is the BFL/Jacob crossbred ewe. I probably could have started a bidding war on her fleece, but I'm keeping it.

A couple of people bagged fleeces after shearing and then each fleece was weighed.

A couple of people bagged fleeces after shearing and then each fleece was weighed.

Alison and Linda helped many new Farm Club members and other visitors evaluate fleeces at the skirting table.

Alison and Linda helped many new Farm Club members and other visitors evaluate fleeces at the skirting table.

The warm afternoon sun was welcome after the cold morning.

The warm afternoon sun was welcome after the cold morning.

Good friendships and sharing the work make a day like this extra fun.

Good friendships and sharing the work make a day like this extra fun.

Wool Handling School

/Last weekend I attended a Wool Handling School presented by the American Sheep Industry. On Sunday we spent the day at Flying Mule Farm in Auburn where the flock was being shorn. It was fun to attend a shearing day and just be a spectator. Lots of photo ops. And lots of learning too.

We spent the day with instructor, Ron Cole, handling wool and learning how to class fleeces. Flying Mule Farm sells most of their wool through the commercial market and it was surprising to me how little skirting is actually done (none other than removing bellies and manure tags). Fleeces that measure in the low 20's (microns) or less would be skirted more carefully, but there is still quite different from what I do. When large flocks are being shorn, the skirting and classing must keep up with the shearing so they have to be quick. No agonizing over every little bit of fleece and of course there is no sorting of color. If there are any black sheep they must be shorn last and that wool kept away from the white wool.

Different parts of the fleece are examined.

Check for strength.

We learned how to throw a fleece. Normally you would pick it up right from the shearing floor and, using this method, throw the fleece on the skirting table. The idea is for the fleece to land cut side down already spread out for classing and/or skirting. In this case the fleeces were handed over the fence and then we all took turns learning to throw them.

I took videos of this as well and will post those when I have time.

Wool was packed into burlap sacks.

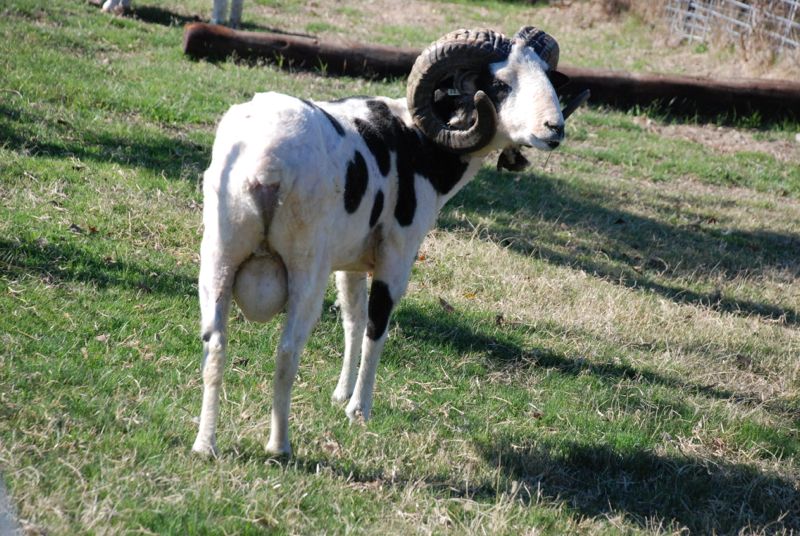

Blue-faced Leicester ram.

The attendees of this school were mostly new and/or small farmers and we spent some time at the end of the day discussing the differences in our perspective from that of larger producers. The focus of this school is how to improve quality and cleanliness of fleeces because all producers who send wool into the commercial market have an effect on the reputation (and therefore value) of U.S. wool in the world market. Farmers like me rely on niche marketing and we have direct contact with our customers. I appreciated this opportunity to learn about other perspectives.

Faulkner & Jerry

/I haven't had time to sort many fleeces yet. In fact, other than those I've sold I have only skirted the ram and wether fleeces. But I'm very happy with those that I've seen.

This is the fleece of a wether, Jerry. He is mostly black, not a good Jacob trait, but he will get to live his life being Faulkner's companion. Faulkner is the BFL ram and I am not going to subject him to living with a group of rams with huge horns.

Faulkner and Jerry

This is what Faulkner's fleece looked like "on the hoof". This photo was taken shortly after I got him so it had grown a lot since then.

This is a lock after shearing.

Less than a minute in hot soapy water.

Silky, white locks!