Close to Home...Post #10 - Sincere Sheep

/One of the first yarns I used when weaving for Close to Home was Targhee wool sold by Sincere Sheep.

Story: Brooke Sinnes of Napa began Sincere Sheep in 2003 and focused on natural dyeing yarn sourced from local wool. Since that time she has included other lines of yarn sourced farther from home.

Sincere Sheep’s Bannock yarn is a 3-ply worsted weight yarn that features 100% Targhee wool from Montana and the Dakotas that is milled in North Carolina and spun in Maine.

The Targhee sheep is named after the Targhee National Forest near where the breed was developed beginning in the 1920’s. The goal of the U.S. Sheep Experiment Station in Idaho was to develop sheep with uniformly heavy fleshing and high quality fine wool that was adapted to rugged conditions of the Western range. Developed by crossing Rambouillet, Corriedale, and Lincoln sheep at the Experiment Station, the Targhee breed was expanded by selection of “Targhee type” ewes from large bands of range ewes crossed with Targhee rams. The flock book was closed in 1966.

Targhee sheep produce 10-12 pound fleeces with very soft, bright white fiber that measures 21-25 microns. Sincere Sheep’s Bannock yarn was named for a Targhee Native American Chief. This is one of only two yarns in this show that are not grown in Solano or Marin Counties but I included it because of the variety of colors, naturally dyed, and the quality of the yarn, and it is grown in the Pacific Northwest, which is Closer to Home than many places where wool is grown.

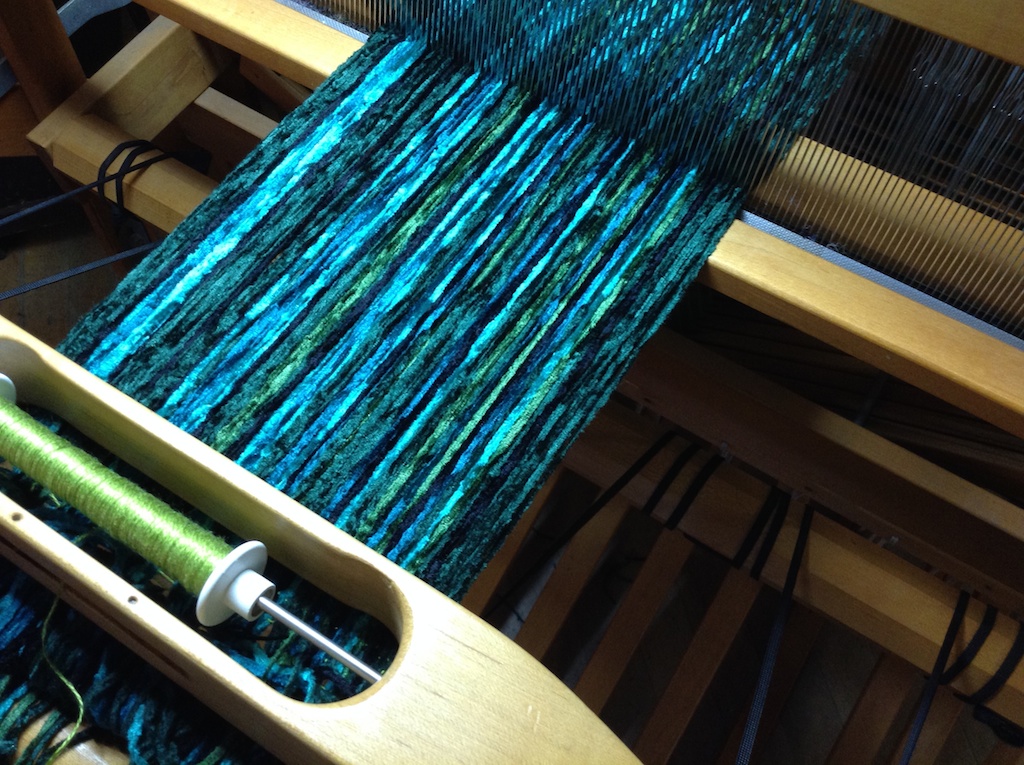

This is one of only two yarns in this show that are not grown in Solano or Marin Counties but I included it because of the variety of colors, naturally dyed, and the quality of the yarn, and it is grown in the Pacific Northwest, which is Closer to Home than many places where wool is grown.  I love the color variation in this yarn...

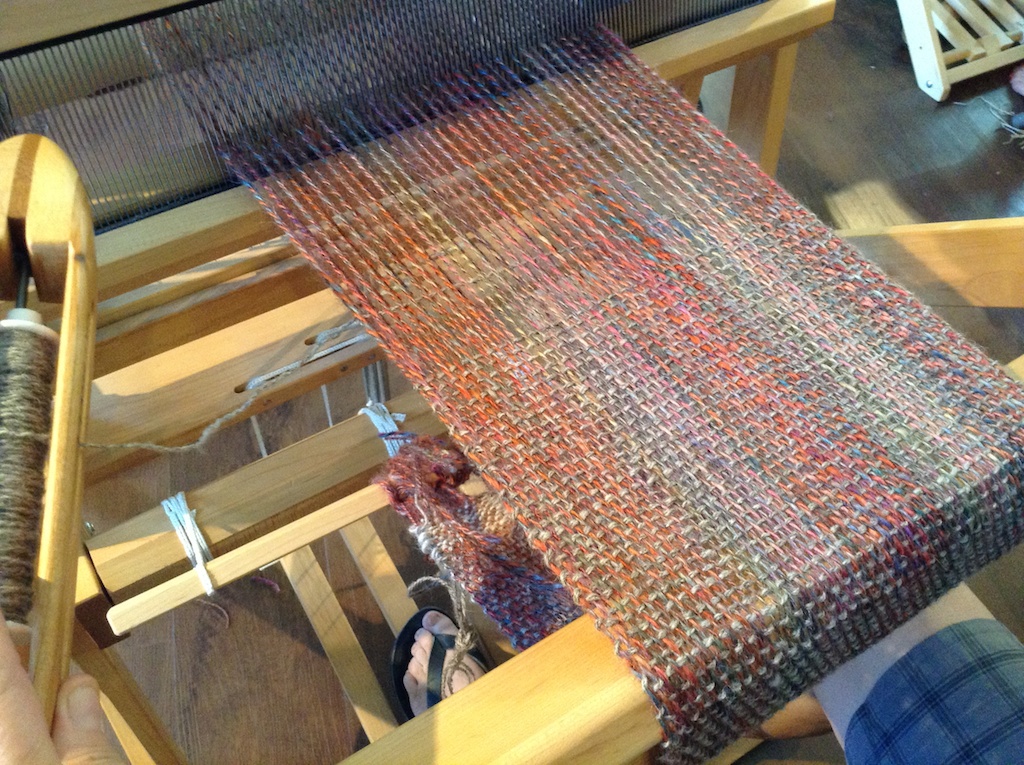

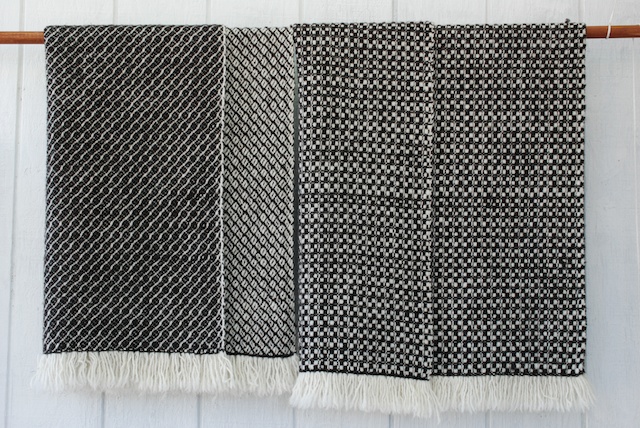

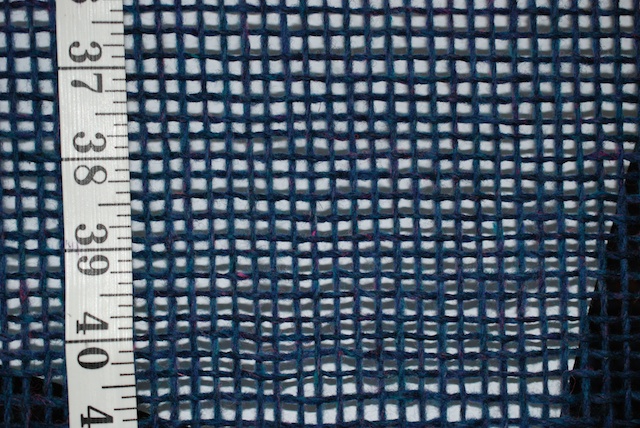

I love the color variation in this yarn... ...and the variety of designs that you can get on one warp.

...and the variety of designs that you can get on one warp.

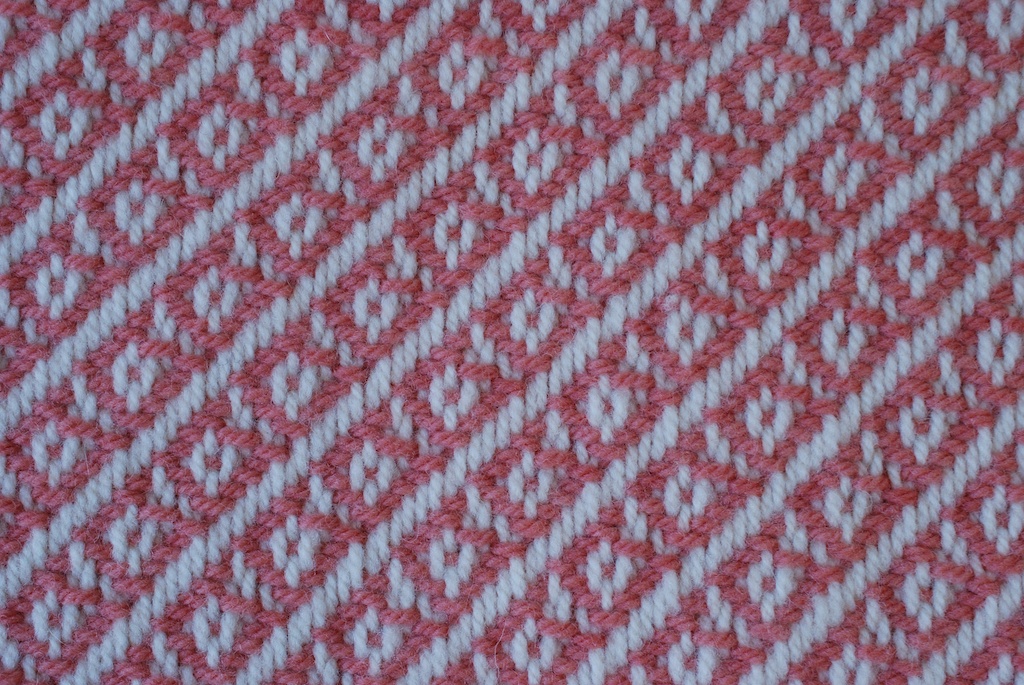

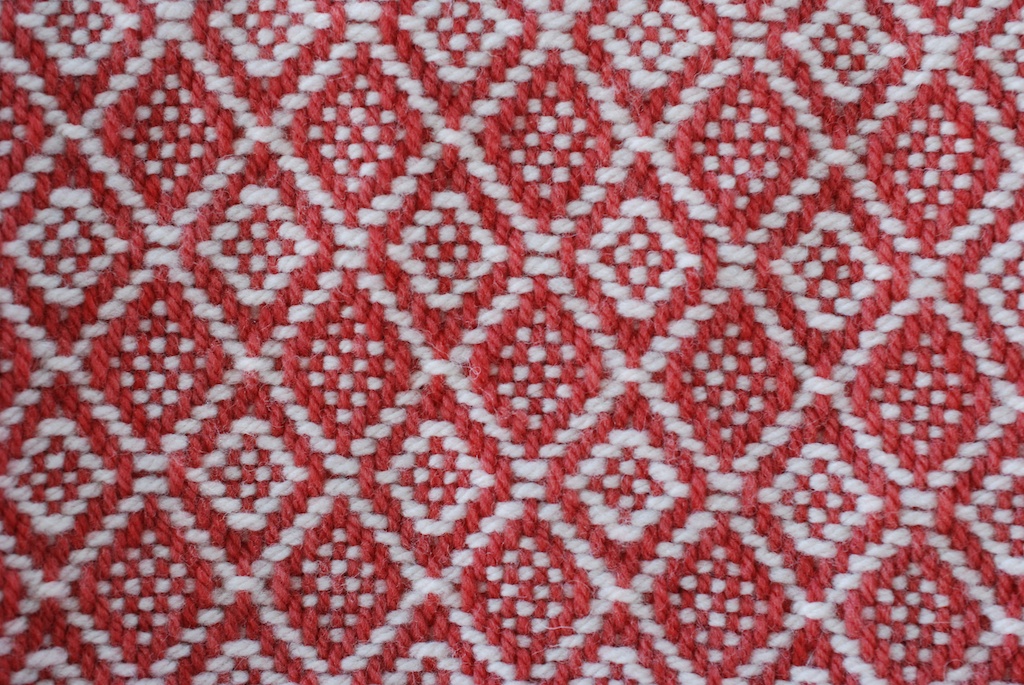

That means that each of the blankets above was woven on the same warp threading in white yarn, but the patterns change by varying the treading and, of course, the color of the weft.

That means that each of the blankets above was woven on the same warp threading in white yarn, but the patterns change by varying the treading and, of course, the color of the weft. Another series of blankets.

Another series of blankets. And another.

And another. At the end of the warp I just wove in white instead of making it plaid and then I felted the fabric. That made great fabric for pillows.

At the end of the warp I just wove in white instead of making it plaid and then I felted the fabric. That made great fabric for pillows. I also wove a series of blankets on a rusty red warp with a white weft

I also wove a series of blankets on a rusty red warp with a white weft

Targhee yarn is very soft and perfect for scarves as well. After the Artery show whatever items are left will be for sale on my website.

Targhee yarn is very soft and perfect for scarves as well. After the Artery show whatever items are left will be for sale on my website.

There were about a dozen people there for the tour even at 9 a.m. on a Monday morning. It was interesting to see the workings of the mill but now I have a lot of unanswered questions. We all wore headsets so that we could hear the tour guide over noise of the mill machinery but that meant that there was no opportunity to ask questions while we were walking. And the tour was fast. I would have liked to stop and watch what was going on with each loom. Now that I'm looking at my photos I realize that I have even more questions about what I was seeing. I guess I'll just have to go back!

There were about a dozen people there for the tour even at 9 a.m. on a Monday morning. It was interesting to see the workings of the mill but now I have a lot of unanswered questions. We all wore headsets so that we could hear the tour guide over noise of the mill machinery but that meant that there was no opportunity to ask questions while we were walking. And the tour was fast. I would have liked to stop and watch what was going on with each loom. Now that I'm looking at my photos I realize that I have even more questions about what I was seeing. I guess I'll just have to go back! The Mill uses Rambouillet wool from Oregon and surrounding states and Merino wool from New Zealand and Australia. The wool is scoured in Texas and then comes to Oregon for spinning and weaving. The carding and spinning equipment was on the second floor. That room was quite humid. The guide told us that high humidity lessons the quantity of airborne particles so employees don't have to wear dust masks. Now I wonder if that is the main reason for the humidity or if it makes carding and spinning more efficient (or both). The photo above shows the carding equipment operating behind plexiglass.

The Mill uses Rambouillet wool from Oregon and surrounding states and Merino wool from New Zealand and Australia. The wool is scoured in Texas and then comes to Oregon for spinning and weaving. The carding and spinning equipment was on the second floor. That room was quite humid. The guide told us that high humidity lessons the quantity of airborne particles so employees don't have to wear dust masks. Now I wonder if that is the main reason for the humidity or if it makes carding and spinning more efficient (or both). The photo above shows the carding equipment operating behind plexiglass.

The sheep are gathered at the back of a trailer that is hauled from ranch to ranch with all the gear. They go up the chute with the encouragement of...

The sheep are gathered at the back of a trailer that is hauled from ranch to ranch with all the gear. They go up the chute with the encouragement of...

Here is a view from the other end of the trailer. That sheep in front hangs out for awhile in that position because the other sheep are more likely to go forward if they see a sheep in front of them. Notice how the sheep walk on a raised alleyway while the freshly shorn fleeces are shoved out of the trailer below them.

Here is a view from the other end of the trailer. That sheep in front hangs out for awhile in that position because the other sheep are more likely to go forward if they see a sheep in front of them. Notice how the sheep walk on a raised alleyway while the freshly shorn fleeces are shoved out of the trailer below them.