I always tell students that unless you are using the exact same yarn in the exact same way that you have used it before, then your project is an experiment. Call it a full-size sample if you want to.

I'm OK with that. Who wants to do the same thing over and over? This is my latest warp. I wound 13 yards of mixed Solano County wool yarns. These are yarns that I have had spun in the last few years from the Timm Ranch, Anderson Ranch, and my own flock. Most were dyed with black walnuts--it's amazing the range of colors you can get when you use a black walnut dye pot over and over...and over. It keeps on giving color. Look at the range of browns in the photo below.

This is my latest warp. I wound 13 yards of mixed Solano County wool yarns. These are yarns that I have had spun in the last few years from the Timm Ranch, Anderson Ranch, and my own flock. Most were dyed with black walnuts--it's amazing the range of colors you can get when you use a black walnut dye pot over and over...and over. It keeps on giving color. Look at the range of browns in the photo below. The other thing to notice about this photo is that the last piece woven on it is so much narrower than the others. This was the fourth shawl on the warp. The one before this one is a different weave structure (advancing twill treadling), but the first two are the same structure as the fourth one. The only difference is the weft yarn. The first three shawls were woven with 2015 Timm Ranch yarn on cones. The weft for the fourth shawl is 2016 Timm Ranch yarn that has been dyed. This is a perfect example of the difference that "finishing" yarn can make.

The other thing to notice about this photo is that the last piece woven on it is so much narrower than the others. This was the fourth shawl on the warp. The one before this one is a different weave structure (advancing twill treadling), but the first two are the same structure as the fourth one. The only difference is the weft yarn. The first three shawls were woven with 2015 Timm Ranch yarn on cones. The weft for the fourth shawl is 2016 Timm Ranch yarn that has been dyed. This is a perfect example of the difference that "finishing" yarn can make.  This is one of the previous batch of shawls. It is mostly Jacob yarn but the weft is last year's Timm Ranch/Jacob blend used from a cone without washing. In this case the width of the warp in the reed was 30" with a sett of 6 epi. That is very open but when wet finished the shawl is lightweight and has great drape. However, the finished width is only about 20" (33% draw-in and shrinkage). So I sett the brown warp the same at 6 epi but started with a 39" wide warp.

This is one of the previous batch of shawls. It is mostly Jacob yarn but the weft is last year's Timm Ranch/Jacob blend used from a cone without washing. In this case the width of the warp in the reed was 30" with a sett of 6 epi. That is very open but when wet finished the shawl is lightweight and has great drape. However, the finished width is only about 20" (33% draw-in and shrinkage). So I sett the brown warp the same at 6 epi but started with a 39" wide warp.

Here are the shawls from the brown warp after wet finishing. That one that was so much narrower on the cloth beam? That is the one that is a little wider here. It is now 27" wide (30% draw-in and shrinkage). The shawl in the same pattern but woven with the white weft is 26" wide (33% draw-in and shrinkage). The difference between width in the reed and the finished piece isn't much, but the photos show the dramatic difference in how the yarn behaves while it is woven.

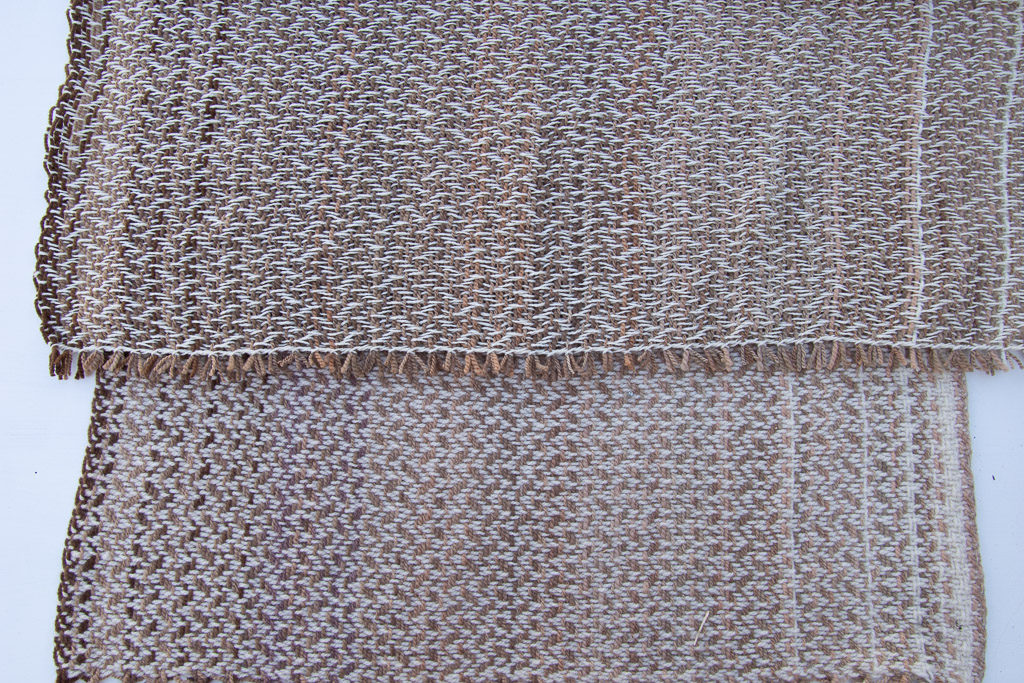

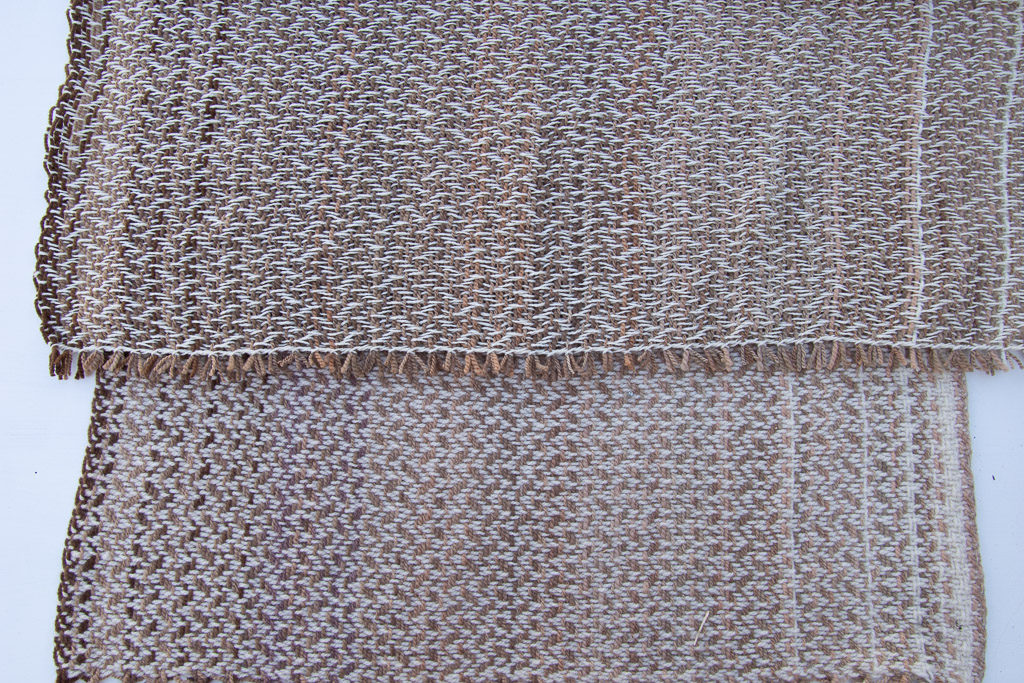

Here are the shawls from the brown warp after wet finishing. That one that was so much narrower on the cloth beam? That is the one that is a little wider here. It is now 27" wide (30% draw-in and shrinkage). The shawl in the same pattern but woven with the white weft is 26" wide (33% draw-in and shrinkage). The difference between width in the reed and the finished piece isn't much, but the photos show the dramatic difference in how the yarn behaves while it is woven.  Here is a before and after photo. The bottom shawl has been wet finished. The top one is the same weft yarn and same pattern, but has not been washed. Look at the very first photo in this post. You can see how wide open the yarns are. Off the loom they are a little closer, but that looks nothing like it will when finished.

Here is a before and after photo. The bottom shawl has been wet finished. The top one is the same weft yarn and same pattern, but has not been washed. Look at the very first photo in this post. You can see how wide open the yarns are. Off the loom they are a little closer, but that looks nothing like it will when finished.  An example of trying to take product photos with the help of a Border Collie.

An example of trying to take product photos with the help of a Border Collie. Here is one of the final product photos. I noticed a surprise. I started to see a purple cast to one of the warp yarns. At first I thought that I just hadn't noticed that shade inside while I was weaving. I tried to convince myself that it was still brown.

Here is one of the final product photos. I noticed a surprise. I started to see a purple cast to one of the warp yarns. At first I thought that I just hadn't noticed that shade inside while I was weaving. I tried to convince myself that it was still brown. Do you see it here?

Do you see it here?  Another photo of one not washed (no purple) and one washed. I lined up the same warp threads in these two pieces.

Another photo of one not washed (no purple) and one washed. I lined up the same warp threads in these two pieces.  Depending on the light setting in the photo (and maybe your monitor) you may see it more clearly in one of these other photos.

Depending on the light setting in the photo (and maybe your monitor) you may see it more clearly in one of these other photos. In person it is clearly visible, although it doesn't stand out.

In person it is clearly visible, although it doesn't stand out.

The answer...that was a yarn dyed with mushrooms from a friend. It must have been rhe soap that caused the shift in color. I love it. Lisa, what is the name of that?

I didn't list this one because right now I can't find it. That may mean it is at the Artery. Or did I sell it? This is what I mean be trying to keep track. I'm not doing very well with that.

I didn't list this one because right now I can't find it. That may mean it is at the Artery. Or did I sell it? This is what I mean be trying to keep track. I'm not doing very well with that. My niece was nice enough to model for me at Thanksgiving.

My niece was nice enough to model for me at Thanksgiving.

Photobombing brother.

Photobombing brother. These are yarns from Lunatic Fringe and all appear in the latest scarf I wove. Hopefully I'll get to that blog before too long.

These are yarns from Lunatic Fringe and all appear in the latest scarf I wove. Hopefully I'll get to that blog before too long.

This is my latest warp. I wound 13 yards of mixed

This is my latest warp. I wound 13 yards of mixed  The other thing to notice about this photo is that the last piece woven on it is so much narrower than the others. This was the fourth shawl on the warp. The one before this one is a different weave structure (advancing twill treadling), but the first two are the same structure as the fourth one. The only difference is the weft yarn. The first three shawls were woven with 2015 Timm Ranch yarn on cones. The weft for the fourth shawl is 2016 Timm Ranch yarn that has been dyed. This is a perfect example of the difference that "finishing" yarn can make.

The other thing to notice about this photo is that the last piece woven on it is so much narrower than the others. This was the fourth shawl on the warp. The one before this one is a different weave structure (advancing twill treadling), but the first two are the same structure as the fourth one. The only difference is the weft yarn. The first three shawls were woven with 2015 Timm Ranch yarn on cones. The weft for the fourth shawl is 2016 Timm Ranch yarn that has been dyed. This is a perfect example of the difference that "finishing" yarn can make.  This is one of the previous batch of shawls. It is mostly Jacob yarn but the weft is last year's Timm Ranch/Jacob blend used from a cone without washing. In this case the width of the warp in the reed was 30" with a sett of 6 epi. That is very open but when wet finished the shawl is lightweight and has great drape. However, the finished width is only about 20" (33% draw-in and shrinkage). So I sett the brown warp the same at 6 epi but started with a 39" wide warp.

This is one of the previous batch of shawls. It is mostly Jacob yarn but the weft is last year's Timm Ranch/Jacob blend used from a cone without washing. In this case the width of the warp in the reed was 30" with a sett of 6 epi. That is very open but when wet finished the shawl is lightweight and has great drape. However, the finished width is only about 20" (33% draw-in and shrinkage). So I sett the brown warp the same at 6 epi but started with a 39" wide warp. Here are the shawls from the brown warp after wet finishing. That one that was so much narrower on the cloth beam? That is the one that is a little wider here. It is now 27" wide (30% draw-in and shrinkage). The shawl in the same pattern but woven with the white weft is 26" wide (33% draw-in and shrinkage). The difference between width in the reed and the finished piece isn't much, but the photos show the dramatic difference in how the yarn behaves while it is woven.

Here are the shawls from the brown warp after wet finishing. That one that was so much narrower on the cloth beam? That is the one that is a little wider here. It is now 27" wide (30% draw-in and shrinkage). The shawl in the same pattern but woven with the white weft is 26" wide (33% draw-in and shrinkage). The difference between width in the reed and the finished piece isn't much, but the photos show the dramatic difference in how the yarn behaves while it is woven.  Here is a before and after photo. The bottom shawl has been wet finished. The top one is the same weft yarn and same pattern, but has not been washed. Look at the very first photo in this post. You can see how wide open the yarns are. Off the loom they are a little closer, but that looks nothing like it will when finished.

Here is a before and after photo. The bottom shawl has been wet finished. The top one is the same weft yarn and same pattern, but has not been washed. Look at the very first photo in this post. You can see how wide open the yarns are. Off the loom they are a little closer, but that looks nothing like it will when finished.  An example of trying to take product photos with the help of a Border Collie.

An example of trying to take product photos with the help of a Border Collie. Here is one of the final product photos. I noticed a surprise. I started to see a purple cast to one of the warp yarns. At first I thought that I just hadn't noticed that shade inside while I was weaving. I tried to convince myself that it was still brown.

Here is one of the final product photos. I noticed a surprise. I started to see a purple cast to one of the warp yarns. At first I thought that I just hadn't noticed that shade inside while I was weaving. I tried to convince myself that it was still brown. Do you see it here?

Do you see it here?  Another photo of one not washed (no purple) and one washed. I lined up the same warp threads in these two pieces.

Another photo of one not washed (no purple) and one washed. I lined up the same warp threads in these two pieces.  Depending on the light setting in the photo (and maybe your monitor) you may see it more clearly in one of these other photos.

Depending on the light setting in the photo (and maybe your monitor) you may see it more clearly in one of these other photos. In person it is clearly visible, although it doesn't stand out.

In person it is clearly visible, although it doesn't stand out.